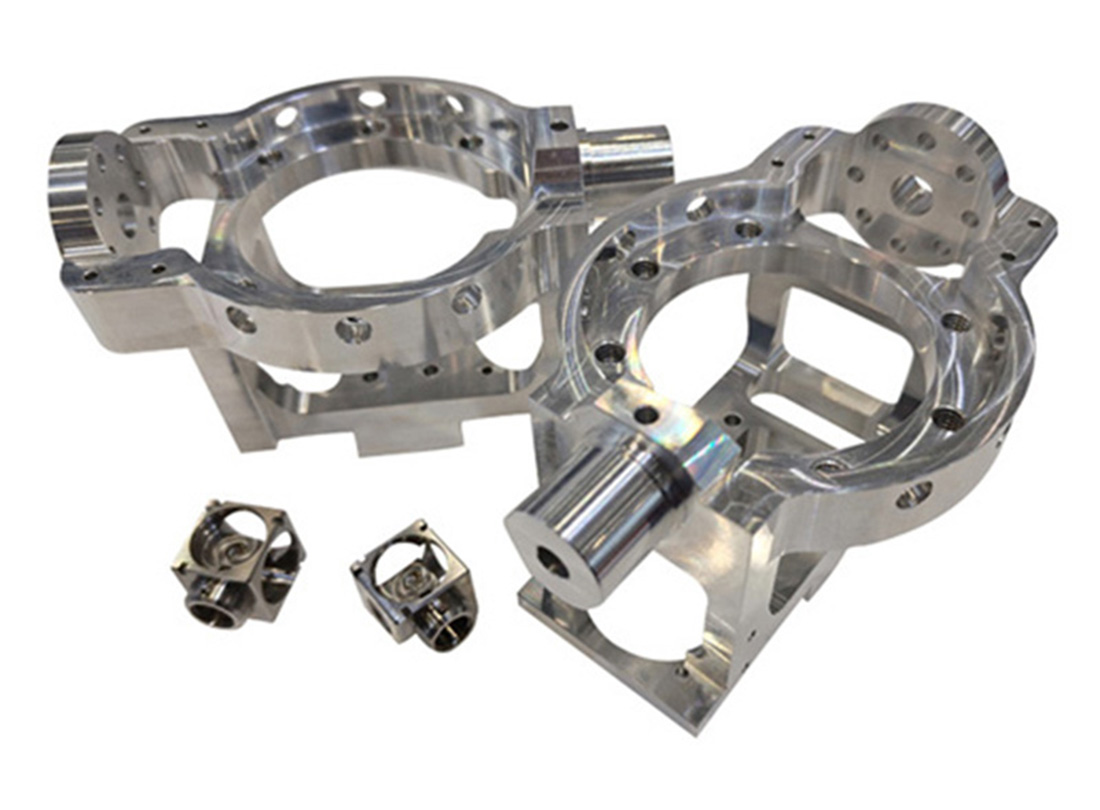

High-quality Electroplating Aluminum CNC Turning Parts

By:Admin

Based in {}, the company has built a solid reputation for delivering top-notch products and services to a wide range of industries, including automotive, aerospace, medical, and electronics. With a strong focus on quality and precision, {} has invested heavily in advanced manufacturing technologies to ensure that their customers receive the best possible solutions for their specific needs.

One of the key capabilities that set {} apart from their competitors is their expertise in electroplating aluminum CNC turning parts. This specialized process involves coating aluminum parts with a thin layer of metal to enhance their surface properties and improve their performance in various applications. By leveraging their state-of-the-art CNC turning machines and extensive knowledge of electroplating techniques, {} is able to produce high-precision, high-performance aluminum parts that meet the stringent requirements of their customers.

The electroplating process at {} begins with the preparation of the aluminum parts, which are carefully cleaned and pretreated to ensure optimal adhesion of the plating material. The parts are then placed in a specialized electroplating bath, where a thin layer of metal is deposited onto their surface through an electrochemical reaction. This metal coating not only improves the appearance of the parts but also provides enhanced corrosion resistance, wear resistance, and electrical conductivity.

With their commitment to excellence, {} has perfected the art of electroplating aluminum CNC turning parts, offering their customers a range of benefits, including improved part longevity, reduced maintenance costs, and enhanced performance in demanding applications. Furthermore, the company's ability to tailor the plating process to meet the unique requirements of each customer's project underscores their dedication to providing customized solutions that exceed expectations.

In addition to their expertise in electroplating, {} also offers a comprehensive range of CNC turning services, utilizing the latest computer-controlled machining centers to produce complex, high-precision parts with utmost efficiency. Their team of skilled machinists and engineers works closely with customers to understand their specific needs, providing valuable insights and technical expertise to optimize the design and manufacturing processes.

The combination of advanced machining capabilities, in-depth material knowledge, and a commitment to quality makes {} a preferred partner for customers seeking reliable and cost-effective solutions for their precision machined part needs. Whether it's creating intricate components for aerospace applications or producing durable parts for the automotive industry, {} has the expertise and resources to deliver exceptional results.

Looking ahead, {} is set to further expand their electroplating and CNC turning capabilities, leveraging emerging technologies and industry best practices to stay ahead of the curve. By continuing to invest in the latest equipment and talent, the company aims to strengthen its position as a leading provider of high-quality precision machined parts, meeting the evolving needs of its customers across industries.

In conclusion, the electroplating aluminum CNC turning parts expertise of {} is a testament to their unwavering commitment to quality, innovation, and customer satisfaction. With a solid track record of delivering excellence, the company is poised to lead the way in the ever-evolving manufacturing landscape, setting new benchmarks for precision and performance in the industry.

Company News & Blog

High-Quality Plastic Mold Components for Various Industries

Plastic Mold Components, a renowned and respected company in the industry, has made a name for itself by providing high-quality and innovative products for the plastic molding industry. With a strong emphasis on precision and reliability, the company has established itself as a leading supplier of mold components and tooling solutions for a wide range of applications.The company's extensive product line includes a variety of mold bases, mold components, hot runner systems, and other essential components for plastic injection molding. These products are designed to meet the demanding requirements of the industry and are built to deliver exceptional performance and durability.One of the key strengths of Plastic Mold Components is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and bring cutting-edge solutions to its customers. This dedication to innovation has enabled the company to develop a range of patented technologies and proprietary products that have set new standards in the industry.In addition to its focus on innovation, Plastic Mold Components is also dedicated to providing superior customer service and support. The company's team of skilled and experienced professionals is committed to working closely with customers to understand their specific needs and provide tailored solutions. Whether it's assisting with product selection, offering technical support, or providing onsite assistance, the team at Plastic Mold Components is always ready to go the extra mile to ensure customer satisfaction.Furthermore, the company's commitment to quality is evident in its rigorous quality control processes and adherence to industry standards. All products undergo strict testing and inspection to ensure they meet the highest standards for performance, reliability, and safety. This dedication to quality has earned Plastic Mold Components a reputation for excellence and reliability in the industry.Beyond its commitment to quality and innovation, Plastic Mold Components also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its environmental footprint and continuously seeks ways to reduce waste, conserve resources, and operate in an environmentally friendly manner. This commitment to sustainability is not only reflected in the company's products but also in its operations and business practices.Looking ahead, Plastic Mold Components is poised for continued growth and success in the industry. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the plastic molding industry and continue to drive progress and excellence.In conclusion, Plastic Mold Components stands as a trusted partner and supplier for companies in the plastic molding industry. With a commitment to quality, innovation, and customer satisfaction, the company continues to deliver cutting-edge solutions and set new standards in the industry. As the company looks to the future, it remains dedicated to driving progress, sustainability, and success in the industry.

High-Quality Rubber Parts for a Variety of Applications

(PR News) - The [Company Name], a leading manufacturer of rubber parts for various industries, has announced the release of their latest line of rubber products. With a strong focus on quality and innovation, the company has established itself as a trusted partner for businesses in need of high-performance rubber parts.The [Company Name] has a rich history of providing top-notch rubber parts to a wide range of industries including automotive, aerospace, electronics, and more. Their commitment to research and development has allowed them to stay ahead of the curve and continuously introduce new and improved products to meet the evolving needs of their customers.With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the [Company Name] has the capability to design and produce custom rubber parts to meet the specific requirements of their clients. Whether it’s rubber seals, gaskets, O-rings, or any other component, the company has the expertise to deliver solutions that exceed expectations.One of the key strengths of the [Company Name] is their focus on quality control. Every product undergoes rigorous testing to ensure that it meets the highest standards for performance and durability. This commitment to quality has earned the company a reputation for reliability and consistency, making them the go-to choice for businesses looking for superior rubber parts.The company’s dedication to innovation is another factor that sets them apart from the competition. They are constantly investing in research and development to explore new materials and manufacturing techniques, with the goal of creating rubber parts that deliver superior performance and longevity. This dedication to pushing the boundaries of what’s possible in rubber technology has made the [Company Name] an industry leader.In addition to their focus on quality and innovation, the [Company Name] also takes pride in their commitment to customer satisfaction. They understand that every business has unique needs and challenges, and they work closely with their clients to provide customized solutions that address those specific requirements. From the initial design phase to the final delivery, the company’s team of experts is there every step of the way to ensure a seamless and successful partnership.The release of the latest line of rubber parts from the [Company Name] underscores their unwavering dedication to excellence. Whether it’s for automotive applications, industrial machinery, or consumer electronics, these new products are designed to deliver superior performance and reliability, making them a valuable asset for businesses in a wide variety of industries.As the demand for high-quality rubber parts continues to grow, the [Company Name] is well-positioned to meet the needs of their customers. With their focus on quality, innovation, and customer satisfaction, they are poised to remain a leader in the industry for years to come.For businesses in need of top-notch rubber parts, the [Company Name] is the partner of choice. With their proven track record of excellence and a commitment to pushing the boundaries of what’s possible, they are a trusted source for high-performance rubber solutions.To learn more about the [Company Name] and their latest line of rubber parts, visit their website at [companywebsite.com] or contact their team directly for more information. With their expertise and dedication, the company stands ready to meet the rubber part needs of businesses around the world.

High-Quality Component Machining for Precision Engineering needs

Precise Component Machining, a leading precision engineering company, is known for its high-quality components and expertise in machining a wide range of materials. The company has built a reputation for delivering precision parts to the aerospace, automotive, medical, and electronics industries. With state-of-the-art technology and a skilled workforce, Precise Component Machining has positioned itself as a key player in the manufacturing sector.Founded in 1990, Precise Component Machining has continuously invested in the latest machining equipment and technologies to meet the evolving demands of its customers. The company's commitment to quality and innovation has allowed it to stay ahead of the competition and maintain long-term relationships with its clients.Precise Component Machining specializes in CNC milling, CNC turning, and Swiss machining, offering a comprehensive range of services to meet the specific needs of its customers. The company's capabilities include the machining of complex shapes and features, tight tolerances, and intricate designs. This level of precision and attention to detail has made Precise Component Machining a preferred partner for companies seeking high-quality components for their products.In addition to its machining capabilities, Precise Component Machining also provides value-added services such as assembly, finishing, and inspection. The company's comprehensive approach to manufacturing ensures that its customers receive fully finished components that meet their exact specifications.One of the key factors that sets Precise Component Machining apart from its competitors is its commitment to continuous improvement. The company regularly invests in training and development programs for its employees to ensure that they are equipped with the skills and knowledge needed to deliver top-notch products. Additionally, Precise Component Machining actively seeks feedback from its customers to identify areas for improvement and to better understand their evolving needs.In recent news, Precise Component Machining has announced the acquisition of a new 5-axis CNC milling machine. This investment will further enhance the company's capabilities and allow it to take on more complex projects with increased efficiency and accuracy. The new machine is equipped with advanced features that will enable Precise Component Machining to produce even tighter tolerances and more intricate designs, solidifying its position as a leader in precision machining."We are thrilled to add this state-of-the-art CNC milling machine to our equipment lineup," said the CEO of Precise Component Machining. "This investment demonstrates our commitment to staying at the forefront of machining technology and providing our customers with the highest quality components."The addition of the new CNC milling machine is just one example of Precise Component Machining's dedication to staying ahead of the curve. The company continues to explore new opportunities for growth and improvement, with a focus on expanding its capabilities and serving a wider range of industries."We are always looking for ways to better serve our customers and meet their ever-changing needs," the CEO continued. "Whether it's investing in new equipment, expanding our expertise, or enhancing our processes, we are committed to providing exceptional products and service."In conclusion, Precise Component Machining is a dynamic and forward-thinking company that is well-positioned to continue its success in the precision engineering industry. With a strong focus on quality, innovation, and customer satisfaction, the company is poised to meet the evolving demands of its customers and maintain its reputation as a leader in precision machining. The acquisition of the new 5-axis CNC milling machine is a testament to Precise Component Machining's commitment to excellence and its determination to remain at the forefront of the industry.

High-Quality Silicone Rubber Molding for Various Applications

Silicone rubber molding is a popular and efficient manufacturing process that is used by various industries to create durable and high-quality products. This process involves using precise molds to shape and cast silicone rubber into a wide range of products, including gaskets, seals, keypads, and other custom components.One company that has become a leader in silicone rubber molding is {Company Name}. With over 20 years of experience in the industry, {Company Name} has established itself as a trusted supplier of silicone rubber products to a diverse range of clients, including those in the automotive, aerospace, medical, and consumer electronics industries. The company is known for its commitment to quality, precision, and customer satisfaction, and has earned a reputation for delivering innovative solutions to its clients' unique manufacturing challenges.At the heart of {Company Name}'s success is its state-of-the-art manufacturing facility, which is equipped with the latest technology and machinery for silicone rubber molding. The company's team of skilled engineers and technicians are experienced in working with a wide range of silicone materials, and are able to provide custom solutions to meet each client's specific requirements. Utilizing advanced CAD/CAM software, {Company Name} is able to quickly design and prototype new products, and is able to efficiently produce high volumes of precision-molded silicone components.One of the key advantages of silicone rubber molding is its ability to produce complex shapes and intricate designs with high precision and accuracy. This makes it an ideal manufacturing process for producing custom gaskets, seals, and other components that require tight tolerances and exacting specifications. Silicone rubber is also known for its excellent resistance to extreme temperatures, chemicals, and environmental conditions, making it an ideal material for a wide range of applications. From automotive gaskets to medical device components, silicone rubber molding offers a versatile and reliable solution for a variety of industries.In addition to its expertise in silicone rubber molding, {Company Name} also offers a range of value-added services to its clients, including product design and development, material selection and testing, and quality assurance and testing. The company is committed to ensuring that all of its products meet the highest standards of quality and performance, and works closely with its clients throughout the entire manufacturing process to ensure that their exact specifications are met.{Company Name} prides itself on its ability to provide innovative solutions to its clients' manufacturing challenges, and is continuously investing in new technologies and processes to further enhance its capabilities. With a focus on quality, precision, and customer satisfaction, {Company Name} is dedicated to delivering exceptional silicone rubber products that meet and exceed its clients' expectations.Overall, silicone rubber molding is a highly effective and versatile manufacturing process that offers a wide range of benefits for a variety of industries. {Company Name} has established itself as a leader in this field, and has demonstrated its expertise in delivering high-quality silicone rubber products to its clients. With its state-of-the-art facility and commitment to innovation, {Company Name} is well positioned to continue providing innovative solutions and exceptional service to its clients for many years to come.

Making High-Quality Injection Molds for Your Manufacturing Needs

Injection Mold Making: A Crucial Component of {}'s Manufacturing ProcessInjection molding is a crucial process in the manufacturing industry, and it often starts with the creation of a mold. A high-quality mold is essential for producing consistent and reliable parts, and that's where {} comes in. As a leader in the injection mold making industry, {} has been providing top-notch mold making services to a wide range of industries for several years.Established in [year], {} has quickly gained a reputation for excellence in the field of mold making. With a state-of-the-art facility and a team of experienced professionals, the company is able to design and manufacture molds that meet the exact specifications of its clients. From simple molds for small components to complex molds for large parts, {} has the expertise and technology to handle any project.The process of mold making at {} begins with a thorough understanding of the client's requirements. The company's team of engineers and designers work closely with the client to create a detailed plan for the mold. Using advanced design software and cutting-edge technology, {} is able to create precise and accurate designs for the mold.Once the design is finalized, {}'s skilled toolmakers get to work on manufacturing the mold. Utilizing CNC machining and traditional craftsmanship, the team at {} ensures that the mold is built to the highest standards. The company's dedication to quality and precision has earned them the trust of numerous clients across various industries.One of the key factors that sets {} apart from its competitors is its commitment to innovation. The company is constantly investing in new technologies and techniques to improve its mold making process. By staying at the forefront of industry advancements, {} is able to offer its clients the most advanced and efficient mold making solutions.In addition to its dedication to technological advancement, {} is also committed to sustainability. The company prioritizes the use of eco-friendly materials and processes in its mold making operations, minimizing its environmental impact. This commitment to sustainability has resonated with clients who value environmentally responsible manufacturing practices.For clients seeking a reliable and efficient partner for mold making, {} offers a comprehensive range of services. The company's expertise extends to the production of injection molds, prototype molds, and high-cavitation molds, among others. With a focus on precision and quality, {} delivers molds that meet the strictest industry standards.The success and reputation of {} in the mold making industry can be attributed to its core values of excellence, integrity, and customer satisfaction. The company's dedication to providing superior mold making solutions has made it a trusted partner for businesses in a multitude of industries.As the manufacturing industry continues to evolve, the demand for high-quality molds will only increase. {} remains at the forefront of this trend, delivering innovative mold making solutions that empower its clients to stay ahead of the competition. With its unwavering commitment to excellence, {} is poised to continue its leadership in the mold making industry for years to come.

Understanding the Process of Injection Molding

Injection molding is a manufacturing process for producing parts by injecting material into a mold. It is commonly used for creating a wide range of products, from plastic toys to automotive parts. With the advancement of technology, injection molding has become more efficient and cost-effective, allowing companies to produce high-quality parts in large quantities.One company that has embraced the use of injection molding is {}. They have established themselves as a leading manufacturer in the industry, utilizing state-of-the-art injection molding machines to meet the demands of their clients. The company has a team of experienced engineers and technicians who are dedicated to delivering top-notch products to their customers.One of the key benefits of injection molding is its ability to produce complex shapes with high precision. This is achieved by designing a custom mold that is filled with the material and then cooled to solidify the part. {}. has invested in advanced mold-making technology to ensure that their products meet the highest standards of quality and accuracy.In addition to precision, injection molding offers fast production speeds, making it an ideal choice for companies looking to mass-produce their products. {}. has multiple injection molding machines, allowing them to fulfill both small and large orders in a timely manner. This has enabled the company to build a reputation for delivering products on time, without compromising on quality.Furthermore, injection molding allows for the use of a wide range of materials, including thermoplastics, metals, and elastomers. This versatility gives companies the flexibility to choose the best material for their specific application. {}. has expertise in working with various materials, ensuring that they can meet the diverse needs of their clients.Another advantage of injection molding is its cost-effectiveness. The process is highly automated, reducing the need for manual labor and minimizing the risk of errors. This helps companies like {} to keep production costs low, making their products more competitive in the market.Moreover, injection molding is an environmentally friendly manufacturing process. It generates minimal waste and allows for the recycling of excess material. As a responsible manufacturer, {}. has implemented sustainable practices in their production process, minimizing their environmental impact.In recent years, the demand for injection-molded products has been on the rise, driven by the growing automotive, consumer goods, and medical industries. {}. has positioned itself as a reliable partner for companies looking to take advantage of the benefits of injection molding. Their commitment to quality, efficiency, and customer satisfaction has earned them a loyal client base and has fueled their growth in the industry.Looking ahead, the company is focused on continuous improvement and innovation. They are exploring new materials and technologies to expand their capabilities and offer even better solutions to their clients. With a strong foundation in injection molding and a dedication to excellence, {}. is well-positioned to remain a leader in the industry for years to come.In conclusion, injection molding is a vital manufacturing process that has revolutionized the production of a wide range of products. {}. has demonstrated a strong commitment to excellence in injection molding, utilizing advanced technology and expertise to deliver high-quality products to their clients. With their focus on precision, efficiency, and innovation, the company is well-equipped to meet the evolving needs of the market and maintain its position as a trusted partner for manufacturing solutions.

Benefits of Small Run Injection Molding for Manufacturing

Small Run Injection Molding (SRI) is a leading manufacturing company specialized in providing high-quality plastic injection molding solutions for small to medium-sized production runs. With a strong focus on quality, precision, and customer satisfaction, SRI has established a solid reputation in the industry for delivering exceptional products to various clients across different sectors.Established over a decade ago, SRI has continuously evolved and expanded its capabilities to meet the ever-growing demands of the market. The company’s state-of-the-art manufacturing facility is equipped with advanced injection molding machines, cutting-edge technologies, and a team of highly skilled professionals who are dedicated to delivering outstanding results. As a full-service provider, SRI offers a comprehensive range of services including product design, tooling, prototyping, and production.SRI takes pride in its ability to cater to the unique needs of its clients, offering flexible solutions that are tailored to their specific requirements. Whether it’s a small batch of custom-designed parts or a medium-sized production run, the company is committed to delivering superior quality products with a quick turnaround time. SRI's expertise in small run injection molding allows businesses to bring their concepts to life and get their products to market in a cost-effective and efficient manner.One of the key differentiators for SRI is its dedication to maintaining the highest standards of quality throughout the production process. The company follows strict quality control protocols to ensure that every product that comes out of its facility meets the exacting specifications of its clients. This commitment to quality has earned SRI the trust and loyalty of its customers, who rely on the company for consistent, reliable, and top-notch results.Additionally, SRI places a strong emphasis on innovation and continuous improvement. The company stays abreast of the latest advancements in injection molding technology and regularly invests in upgrading its infrastructure to stay ahead of the curve. This proactive approach enables SRI to take on challenging projects, push the boundaries of what is possible in injection molding, and deliver innovative solutions to its clients.In line with its commitment to sustainability, SRI also places a high priority on environmental responsibility. The company utilizes eco-friendly materials and processes wherever possible, minimizing its ecological footprint while still delivering high-quality products. By adopting sustainable practices, SRI is contributing to a more environmentally conscious approach to manufacturing.SRI has earned recognition for its excellence in manufacturing and has received accolades for its exceptional performance, reliability, and customer satisfaction. The company's dedication to its craft and its unwavering commitment to exceeding customer expectations have positioned it as a trusted partner for businesses seeking top-tier injection molding solutions.Overall, Small Run Injection Molding (SRI) stands out as a prime example of a manufacturing company that excels in delivering high-quality, precision-engineered products for small to medium-sized production runs. With its focus on innovation, quality, and customer satisfaction, SRI continues to solidify its position as a leader in the injection molding industry, setting new benchmarks for excellence and reliability. Whether it's a custom project or a standard production run, SRI is the go-to choice for businesses looking for exceptional injection molding solutions.

Advanced Laser Prototyping Techniques for Rapid Product Development

Laser Prototyping Technology Revolutionizes Manufacturing IndustryLaser prototyping technology has become the latest game changer in the manufacturing industry, and {} is at the forefront of this innovative method. With laser prototyping, the traditional process of creating prototypes and small-scale production parts has been redefined. This cutting-edge technology allows for faster and more precise manufacturing, making it a game-changer for companies looking to stay ahead of the curve in their respective industries.Laser prototyping, also known as laser sintering or laser melting, uses a high-powered laser to selectively fuse powdered material to create three-dimensional objects. This process allows for the production of complex and intricate parts and prototypes with a level of precision that was previously unattainable with traditional manufacturing methods. The result is a higher quality product that can be produced in a fraction of the time compared to conventional manufacturing processes.{} has been at the forefront of laser prototyping technology, developing state-of-the-art equipment that has revolutionized the manufacturing industry. With a strong commitment to innovation and quality, {} has become a leader in the field of laser prototyping and has helped countless companies improve their manufacturing processes.One of the key advantages of laser prototyping is its ability to produce parts and prototypes with intricate geometries and complex designs. Traditional manufacturing methods often struggle to produce such intricate parts, but with laser prototyping, companies can create virtually any design without the limitations of traditional manufacturing processes. This has opened the door to new possibilities in product development and has empowered companies to bring their most ambitious ideas to life.In addition to its ability to produce complex designs, laser prototyping also offers significant time and cost savings. The speed and efficiency of the laser prototyping process mean that companies can rapidly produce prototypes and small-scale production parts without the need for expensive tooling or lengthy lead times. This has been a game-changer for companies looking to streamline their manufacturing processes and bring products to market faster than ever before.Furthermore, laser prototyping technology is also more environmentally friendly than traditional manufacturing methods. The process produces little to no waste, as any unused powder can be recycled and reused in future production runs. This not only reduces the environmental impact of manufacturing but also helps companies save on material costs, making laser prototyping a cost-effective and sustainable option for modern manufacturing.With {}'s cutting-edge laser prototyping technology, companies across a wide range of industries have been able to improve their manufacturing processes and bring their products to market faster and more efficiently than ever before. From aerospace and automotive to healthcare and consumer goods, laser prototyping has had a transformative impact on how companies approach product development and manufacturing.Looking ahead, the future of laser prototyping looks bright, with further advancements and innovations on the horizon. {} is committed to pushing the boundaries of what is possible with laser prototyping, and the company is continuously working to develop new technologies and techniques that will further revolutionize the manufacturing industry.As more companies recognize the benefits of laser prototyping, it's clear that this cutting-edge technology will play an increasingly important role in the future of manufacturing. With its ability to produce complex designs, reduce lead times, and minimize environmental impact, laser prototyping is a game-changer that is set to reshape the manufacturing industry for years to come. And with {} leading the way in innovation and quality, the future of laser prototyping looks brighter than ever.

The Benefits of Complex Injection Molding technology

Complex injection molding is an advanced manufacturing process that allows for the production of highly intricate and detailed plastic parts. This process involves injecting molten plastic into a mold, which is then cooled and solidified to create the desired part. Complex injection molding is a key technology for a wide range of industries, including automotive, electronics, medical devices, and consumer goods.One company that has established itself as a leader in complex injection molding is {}, a global provider of high-quality plastic components and assemblies. With a focus on innovation and precision engineering, {} has earned a reputation for delivering cutting-edge solutions to its customers' most demanding challenges.Founded in {}, {} has grown into a multi-national corporation with facilities in several countries around the world. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing {} to offer a wide range of complex injection molding capabilities. From micro-molding to large-format molding, {} has the expertise and capabilities to handle the most complex and challenging projects.One of the key strengths of {} is its ability to work closely with customers to develop custom solutions that meet their specific needs. The company's team of engineers and designers use advanced 3D modeling and simulation tools to develop highly optimized mold designs, ensuring that the final products meet the strictest quality and performance requirements. In addition, {}'s expertise in material selection and process optimization allows the company to deliver cost-effective solutions without compromising on quality.{}'s commitment to quality is exemplified by its rigorous quality assurance processes. The company's facilities are certified to the highest industry standards, including ISO 9001 and ISO 13485, ensuring that every part manufactured by {} meets the strictest quality and regulatory requirements. In addition, {} employs advanced inspection and testing techniques to guarantee the integrity and performance of its products, providing customers with added confidence in the reliability of their components.In addition to its technical expertise, {} is also known for its dedication to sustainability and environmental responsibility. The company has implemented a range of initiatives to reduce its environmental impact, including energy-efficient manufacturing processes, waste reduction programs, and the use of recyclable materials. By incorporating sustainable practices into its operations, {} is able to deliver high-quality products while minimizing its footprint on the environment.Looking ahead, {} is well-positioned to continue its leadership in complex injection molding. The company is investing in new technologies and capabilities to expand its offerings and serve an even broader range of industries and applications. In addition, {} continues to invest in its people, with ongoing training and development programs to ensure that its team remains at the forefront of the industry.As the demand for complex plastic components continues to grow, {} is poised to play a key role in shaping the future of manufacturing. With its unwavering commitment to quality, innovation, and sustainability, {} is a trusted partner for companies looking to bring their most complex and challenging projects to life. With its advanced capabilities and customer-focused approach, {} is well-equipped to meet the evolving needs of the market and drive the next generation of complex injection molding solutions.

Understanding the Importance of Precision in CNC Machining

CNC Precision, a leading precision machining company, has recently announced its expansion plans to meet the growing demand for its services in the manufacturing industry. The company, which specializes in providing high-quality CNC machining, has built a reputation for delivering precision parts and components to a wide range of industries, including aerospace, automotive, medical, and electronics.With the increasing demand for precision-machined parts and components, CNC Precision has recognized the need to expand its operations in order to better serve its customers. The company has invested in state-of-the-art equipment and technology to increase its production capacity and capabilities, allowing it to take on larger and more complex projects. This expansion will enable CNC Precision to meet the evolving needs of its customers and maintain its position as a market leader in the precision machining industry."We are excited to announce our expansion plans as we strive to meet the growing demand for our precision machining services," said the CEO of CNC Precision. "Our investment in new technology and equipment will enable us to provide our customers with even higher quality products and faster turnaround times. This expansion is a testament to our commitment to being a reliable and innovative partner for our customers."In addition to increasing its production capacity, CNC Precision is also focused on expanding its workforce to accommodate the growing demand for its services. The company is actively recruiting skilled machinists, engineers, and support staff to join its team and contribute to its continued success. By investing in its team and facilities, CNC Precision aims to continue providing exceptional service and value to its customers.As part of its expansion plans, CNC Precision is also exploring opportunities to broaden its customer base and expand its presence in new markets. The company is actively seeking partnerships and collaborations with other organizations in the manufacturing industry to further enhance its capabilities and reach. By forging strategic alliances, CNC Precision aims to leverage its expertise and resources to deliver added value to its customers and accelerate its growth.CNC Precision's commitment to innovation, quality, and customer satisfaction has been the driving force behind its success. The company's dedication to investing in advanced technology, expanding its capabilities, and attracting top talent has positioned it as a trusted partner for a wide range of industries. As CNC Precision continues to expand and evolve, it remains focused on delivering precision solutions that meet the unique needs of its customers.The expansion of CNC Precision comes at a time when the manufacturing industry is experiencing rapid growth and transformation. With increasing demand for precision-machined parts and components, companies are seeking reliable partners that can deliver high-quality products with quick turnaround times. CNC Precision's expansion plans align with the industry's needs, positioning the company for continued success and leadership in the precision machining sector.As CNC Precision continues to expand its operations and capabilities, it remains dedicated to delivering exceptional quality and service to its customers. The company's expansion plans underscore its commitment to meeting the evolving needs of the manufacturing industry and driving innovation in precision machining. With its growing team, advanced technology, and strategic partnerships, CNC Precision is well-positioned to continue setting the standard for precision machining and delivering value to its customers.