The Advantages of Precision Injection in Manufacturing

By:Admin

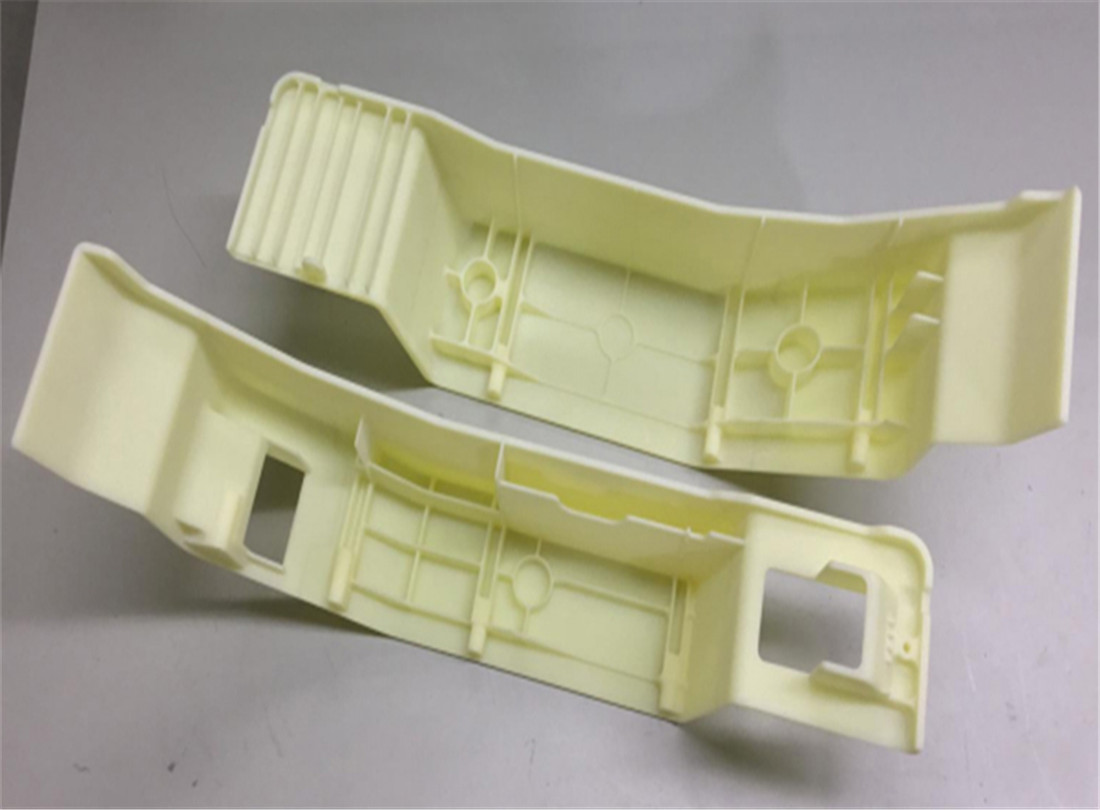

Founded over 20 years ago, Precision Injection has continually evolved and adapted to meet the ever-changing demands of the industry. The company's state-of-the-art facilities are equipped with the latest machinery and equipment, allowing them to produce high-quality products with exceptional precision and accuracy.

One of Precision Injection's core strengths lies in its ability to work closely with clients to develop customized solutions that meet their specific needs. The company's team of experienced engineers and designers are dedicated to finding creative and cost-effective ways to bring their clients' visions to life.

Precision Injection's commitment to excellence is reflected in its stringent quality control measures. Every product that leaves the facility undergoes rigorous testing to ensure that it meets the highest standards of quality and performance. This attention to detail has earned the company a reputation for reliability and consistency, making them the go-to choice for clients across a wide range of industries.

In addition to their dedication to quality, Precision Injection is also committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and materials, minimizing their carbon footprint and impact on the environment. This focus on sustainability has not only earned the company the respect of its peers but has also resonated with environmentally conscious clients looking for a responsible manufacturing partner.

Precision Injection's wide range of capabilities extends to various industries, including automotive, medical, consumer goods, and more. The company's expertise in producing complex and intricate parts has made them a valuable partner for clients with high-performance requirements. From small, intricate components to large, durable parts, Precision Injection has the capacity and expertise to handle projects of all sizes and complexities.

The company's success can be attributed to its relentless pursuit of innovation and improvement. Precision Injection continually invests in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This forward-thinking approach has enabled the company to remain at the forefront of the industry and anticipate and meet the evolving needs of its clients.

In recognition of its excellence, Precision Injection has received several accolades and certifications, further solidifying its reputation as a leader in the field. The company's dedication to the highest standards of quality and service has earned it the trust and loyalty of a diverse and prestigious client base.

Looking to the future, Precision Injection remains committed to its core values of quality, innovation, and customer satisfaction. With a focus on continuous improvement and a keen eye on emerging trends and technologies, the company is poised to continue its upward trajectory and maintain its position as a top-tier manufacturer in the industry.

In conclusion, Precision Injection stands as a shining example of excellence in the field of plastic injection molding. With its commitment to quality, innovation, and sustainability, the company has carved out a niche for itself as a trusted and reliable partner for clients across various industries. As they continue to push the boundaries of what is possible in plastic injection molding, Precision Injection is undoubtedly a force to be reckoned with in the industry.

Company News & Blog

High-Quality Rubber Gasket for Various Applications: A Complete Guide

Square Rubber Gasket Introduces Advanced Technology to Improve Sealing SolutionsWith the increasing demand for high-quality sealing solutions in various industries, Square Rubber Gasket has emerged as a leading provider of innovative rubber gaskets. The company, known for its commitment to excellence and customer satisfaction, has recently introduced advanced technology to further enhance its sealing solutions, setting a new standard in the industry.Based in (location), Square Rubber Gasket has established a strong presence in the market since its inception. Specializing in the production of custom rubber gaskets for a wide range of applications, including automotive, aerospace, marine, and industrial equipment, the company has built a reputation for delivering reliable and durable sealing solutions.The newly introduced advanced technology by Square Rubber Gasket is set to revolutionize the way rubber gaskets are manufactured and used. This innovative technology incorporates state-of-the-art materials, precision engineering, and advanced manufacturing processes to ensure superior performance and durability of the gaskets.One of the key features of the advanced technology is its ability to customize rubber gaskets according to specific customer requirements. This level of customization allows Square Rubber Gasket to meet the unique needs of different industries and applications, ensuring a perfect fit and optimal sealing performance.In addition, the advanced technology enables the production of rubber gaskets with enhanced resistance to extreme temperatures, pressure, and chemical exposure. This makes the gaskets suitable for use in the harshest operating conditions, providing long-term reliability and safety.Moreover, the newly introduced technology allows for improved efficiency in the manufacturing process, resulting in faster lead times and cost-effective solutions for customers. By streamlining production and optimizing material usage, Square Rubber Gasket is able to offer competitive pricing without compromising on quality.The introduction of this advanced technology underscores Square Rubber Gasket's commitment to innovation and continuous improvement. "We are dedicated to meeting the evolving needs of our customers and providing them with cutting-edge sealing solutions that exceed their expectations," said (spokesperson's name), (title) at Square Rubber Gasket.Furthermore, the company's investment in advanced technology demonstrates its dedication to sustainability and environmental responsibility. By utilizing efficient manufacturing processes and eco-friendly materials, Square Rubber Gasket strives to reduce its carbon footprint and contribute to a greener future.As part of its commitment to quality assurance, Square Rubber Gasket maintains strict quality control measures at every stage of the production process. This ensures that every rubber gasket meets the highest standards of performance, reliability, and durability.Customers can also benefit from Square Rubber Gasket's technical expertise and responsive customer support. The company's team of experienced engineers and technicians are available to provide comprehensive guidance and assistance, from design concept to post-installation support.The introduction of advanced technology by Square Rubber Gasket has already garnered significant attention in the industry, with many customers expressing interest in exploring the new possibilities it offers. As the company continues to expand its presence and capabilities, it is poised to set new benchmarks for excellence in the sealing solutions market.In conclusion, Square Rubber Gasket's introduction of advanced technology represents a significant milestone in the evolution of rubber gaskets. With its focus on innovation, customization, sustainability, and quality, the company is well-positioned to meet the diverse needs of its customers and lead the way towards a future of enhanced sealing solutions.

Injection Molding Services: What You Need to Know for Your Project

Introducing a more efficient and cost-effective injection molding solution for manufacturing prototypes and low-volume production parts. With the latest technology and a team of skilled engineers, our company is revolutionizing the industry with a faster and more affordable process for producing high-quality plastic parts.Traditional injection molding processes often involve long lead times, high tooling costs, and minimum order quantities that can be a barrier for many businesses, especially those looking to test new product designs or produce small quantities of parts. However, with Protomold Injection Molding, these challenges are a thing of the past. Our advanced injection molding technology allows for quick turnaround times, low upfront tooling costs, and the flexibility to produce as few as one part, making it possible for businesses of all sizes to bring their ideas to life.One of the key advantages of Protomold Injection Molding is its ability to produce high-quality parts with complex geometries and fine details. Our state-of-the-art molding process, combined with the expertise of our team, ensures that the parts produced are precise, durable, and consistent, meeting the highest industry standards.In addition to the quality of the parts produced, our company takes pride in its customer-centric approach. From the initial concept to the final product, our team works closely with each client to understand their needs and provide tailored solutions. Whether it's a prototype for a new product or a low-volume production run, we are committed to delivering the best results in a timely manner.Furthermore, our company is dedicated to sustainability and environmental responsibility. We use advanced materials and processes that minimize waste and energy consumption, ensuring that our injection molding solutions are not only efficient and cost-effective but also eco-friendly.With Protomold Injection Molding, businesses can now accelerate their product development cycles, reduce time to market, and minimize overall production costs. The combination of speed, flexibility, and high-quality results makes our injection molding solution the preferred choice for companies across various industries, including automotive, aerospace, medical devices, consumer electronics, and more.In conclusion, our company is proud to offer a game-changing injection molding solution that is reshaping the way businesses prototype and manufacture plastic parts. With our advanced technology, skilled engineers, and customer-centric approach, we are committed to helping our clients bring their ideas to life quickly, affordably, and sustainably. Whether it's a one-off prototype or a low-volume production run, our injection molding solution is the key to unlocking new possibilities for businesses of all sizes. Contact us today to learn more about how we can help bring your vision to reality.

Durable Rubber Gasket for Industrial Use: A Comprehensive Guide

Square Rubber Gasket, a leading manufacturer in the rubber gasket industry, has recently unveiled its latest product designed to meet the ever-growing demand for high-quality and reliable gaskets in various industrial applications. With a history of excellence and innovation, Square Rubber Gasket has set itself apart as a trusted source for superior rubber gaskets.Established in [year], Square Rubber Gasket has built a solid reputation for delivering top-notch gaskets that excel in performance, durability, and effectiveness. The company is committed to utilizing advanced manufacturing techniques and high-quality materials to produce gaskets that meet or exceed industry standards. With a focus on customer satisfaction and engineering excellence, Square Rubber Gasket has become a preferred choice for businesses seeking reliable sealing solutions.The newly launched square rubber gasket is the latest addition to Square Rubber Gasket's extensive product line. Engineered to precise specifications, this gasket is designed to provide exceptional sealing performance in a wide range of applications. The square shape of the gasket offers unique advantages, including enhanced stability and a tight seal, making it an ideal choice for various industrial equipment and machinery."We are thrilled to introduce our latest square rubber gasket to the market," said [spokesperson]. "This new product showcases our dedication to innovation and our commitment to meeting the evolving needs of our customers. We are confident that this gasket will deliver outstanding performance and reliability, further solidifying our position as a leader in the industry."The square rubber gasket is manufactured using advanced rubber compounds that offer superior resilience, resistance to heat and chemicals, and long-lasting durability. These properties make the gasket suitable for use in demanding environments where reliable sealing is crucial. Additionally, the square shape of the gasket provides enhanced stability and uniform compression, ensuring a tight and secure seal.One of the key advantages of the square rubber gasket is its versatility. It can be used across various industries, such as automotive, aerospace, marine, manufacturing, and many others. Whether it is sealing components in heavy machinery or providing insulation in electrical enclosures, the square rubber gasket offers a reliable solution for a wide range of applications.Square Rubber Gasket's commitment to quality and excellence extends beyond its products. The company's dedication to providing exceptional customer service and technical support has earned it a loyal and satisfied customer base. With a team of experienced engineers and industry experts, Square Rubber Gasket works closely with its clients to understand their specific sealing requirements and provide customized solutions that meet their needs.As a responsible and environmentally conscious manufacturer, Square Rubber Gasket takes great care to ensure its production processes are sustainable and eco-friendly. The company complies with all relevant regulations and standards, and it continuously seeks to minimize its environmental impact through efficient use of resources and waste reduction.In conclusion, Square Rubber Gasket's latest square rubber gasket represents a significant advancement in sealing technology. With its precision engineering, exceptional performance, and versatility, this gasket is poised to set new standards in the industry. As Square Rubber Gasket continues to push the boundaries of innovation and quality, it remains a trusted partner for businesses seeking reliable sealing solutions. With its unwavering commitment to excellence and customer satisfaction, Square Rubber Gasket is set to maintain its position as a leader in the rubber gasket industry.

High Precision CNC Machining Services for Your Business Needs

CNC Precision Manufacturing Company Leads the Industry with State-of-the-Art TechnologyIn the fast-paced world of manufacturing, precision is paramount. From small components to large-scale productions, precision in manufacturing is the key to success. This is where CNC Precision Manufacturing Company has set itself apart from the competition. With their cutting-edge technology and commitment to excellence, they have become a leading force in the industry.CNC Precision Manufacturing Company, based in (location), has been at the forefront of the manufacturing industry for over 20 years. Specializing in precision machining and fabrication, the company has built a reputation for delivering top-quality products to a wide range of industries, including aerospace, automotive, medical, and defense.The company's success can be attributed to its state-of-the-art facility, which is fully equipped with the latest CNC machines, robotic arms, and advanced software. This allows the team of highly skilled engineers and technicians to produce components with unparalleled accuracy and efficiency. The company's dedication to investing in cutting-edge technology has allowed them to stay ahead of the curve and meet the ever-changing demands of the market.One of the key factors that has set CNC Precision Manufacturing Company apart from its competitors is its commitment to innovation. The company constantly seeks new ways to improve its processes and enhance its capabilities. By investing in research and development, the company has been able to develop innovative solutions that have revolutionized the manufacturing process. This has allowed them to produce complex components with intricate designs and tight tolerances, giving them an edge in the market.Furthermore, CNC Precision Manufacturing Company has a strong emphasis on quality control. Every component goes through a rigorous inspection process to ensure that it meets the highest standards. This dedication to quality has earned the company numerous certifications and accolades, making it a trusted partner for companies that demand precision and reliability in their components.In addition to its technical capabilities, CNC Precision Manufacturing Company places a significant emphasis on customer satisfaction. The team works closely with its clients to understand their specific needs and requirements, offering personalized solutions that meet and exceed their expectations. This customer-centric approach has solidified the company's reputation as a reliable and trusted partner in the industry.CNC Precision Manufacturing Company's commitment to excellence has not gone unnoticed. The company has received numerous awards and recognition for its outstanding performance and contributions to the industry. With a strong track record of delivering exceptional products and services, the company continues to be a leading force in the manufacturing sector.Looking ahead, CNC Precision Manufacturing Company remains dedicated to pushing the boundaries of innovation in manufacturing. With a focus on continuous improvement and a forward-thinking approach, the company is poised to continue setting new standards in precision machining and fabrication. As the industry continues to evolve, CNC Precision Manufacturing Company is committed to staying at the forefront of technological advancements and delivering superior products that meet the demands of the modern manufacturing landscape.For companies that demand the highest level of precision and quality in their components, CNC Precision Manufacturing Company stands ready to deliver. With its cutting-edge technology, commitment to innovation, and dedication to customer satisfaction, the company is poised to lead the industry for years to come.

Leading Manufacturer of Silicon Parts: Advantages and Applications

Silicone Parts Manufacturer Leads the Industry with Innovative Technology and Quality ProductsAs the demand for silicone parts continues to rise in various industries, one company has been at the forefront of innovation and quality manufacturing. With a commitment to excellence and a focus on customer satisfaction, [Silicone Parts Manufacturer] has established itself as a leader in the industry.Based in [Location], [Silicone Parts Manufacturer] has been serving customers around the world for over [number] years. The company specializes in the design and production of high-quality silicone parts for a wide range of applications, including automotive, medical, aerospace, and consumer electronics.One of the key factors that sets [Silicone Parts Manufacturer] apart from its competitors is its dedication to innovation. The company invests heavily in research and development to stay ahead of the curve and to continually improve its products and processes. This commitment to innovation has led to the development of several groundbreaking technologies and manufacturing techniques that have revolutionized the industry.In addition to its innovative approach, [Silicone Parts Manufacturer] also prioritizes quality in every aspect of its operations. The company uses only the highest-grade materials and state-of-the-art equipment to ensure that its products meet the highest standards of excellence. From design and prototyping to production and inspection, every step of the manufacturing process is meticulously monitored to guarantee the utmost quality.Furthermore, [Silicone Parts Manufacturer] holds several certifications and accreditations, demonstrating its dedication to maintaining the highest levels of quality and safety. The company is ISO [Number] and [Other Certification] certified, which reflects its adherence to stringent quality management systems and industry best practices.One of the company's most notable achievements is its development of a proprietary silicone molding process, which allows for the production of complex and intricate parts with unparalleled precision and detail. This innovative technology has enabled [Silicone Parts Manufacturer] to offer customized solutions to meet the unique needs of its customers, setting it apart as a trusted partner for companies across diverse industries.In addition to its commitment to innovation and quality, [Silicone Parts Manufacturer] also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and to provide tailored solutions that meet and exceed their expectations. With a dedicated team of skilled professionals, [Silicone Parts Manufacturer] is able to offer comprehensive support and guidance throughout the entire product development and manufacturing process.As a result of its relentless pursuit of excellence, [Silicone Parts Manufacturer] has earned a reputation as a trusted and reliable partner in the industry. The company has established long-term relationships with many industry-leading companies, who rely on its expertise and capabilities to deliver superior silicone parts that are critical to their products and operations.Looking to the future, [Silicone Parts Manufacturer] remains committed to pushing the boundaries of innovation and quality in the silicone parts industry. The company continues to invest in research and development, with a focus on developing new technologies and materials that will further enhance its product offerings and manufacturing capabilities. Additionally, [Silicone Parts Manufacturer] is exploring opportunities to expand its presence in emerging markets and to further strengthen its position as a global leader in the industry.For companies seeking a trusted partner for high-quality silicone parts, [Silicone Parts Manufacturer] stands out as a proven industry leader that is dedicated to delivering excellence in every aspect of its operations. With its innovative technologies, uncompromising commitment to quality, and customer-centric approach, [Silicone Parts Manufacturer] is poised to continue setting the standard for excellence in the industry for years to come.

Top-quality Plastic Injection Moulding Services for Precision Manufacturing

Precision plastic injection moulding is a critical manufacturing process that involves creating custom plastic parts by injecting molten plastic material into a mould. This process requires extreme precision and expertise to ensure that the final product meets the exact specifications and requirements of the client. With the advancement of technology and the increasing demand for high-quality plastic parts, precision plastic injection moulding has become an essential part of many industries, including automotive, aerospace, medical, and consumer goods.With a commitment to providing high-quality and precise plastic injection moulding services, {} has established itself as a leading manufacturer in the industry. The company's dedication to excellence and continuous improvement has allowed them to consistently deliver top-notch products to their clients, making them a trusted partner in the manufacturing sector.{} possesses state-of-the-art facilities and cutting-edge technology that enables them to produce complex and intricate plastic parts with the highest level of accuracy and precision. Their team of experienced engineers and technicians are well-versed in the latest moulding techniques and are capable of handling even the most challenging projects.The company has a comprehensive range of injection moulding machines that are capable of handling various plastic materials, including ABS, polycarbonate, polypropylene, and more. This versatility allows them to cater to a wide range of industries and applications, offering custom solutions that meet the unique needs of each client.In addition to their advanced capabilities, {} also places a strong emphasis on quality control and assurance. Every product that comes out of their facility undergoes rigorous testing and inspection to ensure that it meets the highest standards of quality and reliability. This dedication to quality has earned {} a stellar reputation in the industry, with many clients returning to them for their plastic injection moulding needs.One of the key factors that sets {} apart from other manufacturers is their ability to provide end-to-end solutions. From the initial design and prototyping phase to the final production and assembly, {} is able to guide their clients through every step of the process, ensuring a seamless and efficient experience. This comprehensive approach allows them to deliver fully integrated solutions that streamline the manufacturing process and reduce time-to-market for their clients.Furthermore, {} is committed to sustainability and environmental responsibility in their operations. They have implemented various initiatives to minimize waste, reduce energy consumption, and optimize their manufacturing processes to have a minimal impact on the environment. This dedication to sustainable practices aligns with the growing focus on eco-friendly manufacturing and has positioned {} as a progressive and conscientious partner in the industry.As the demand for precision plastic parts continues to grow in various industries, {} remains at the forefront of the market, offering innovative solutions, top-quality products, and exceptional customer service. With a track record of success and a steadfast commitment to excellence, {} is poised to continue making significant contributions to the manufacturing sector and solidify its position as a leader in precision plastic injection moulding.In conclusion, precision plastic injection moulding is a critical process that requires expertise, innovation, and precision. As a trusted leader in the industry, {} has demonstrated their ability to deliver exceptional products and services, setting the bar for quality and reliability. With a strong focus on continuous improvement and sustainability, {} is well-positioned to meet the evolving needs of the market and remain a preferred partner for clients seeking high-quality plastic injection moulding solutions.

The Advantages of Precision Injection in Manufacturing

Precision Injection, a leading manufacturer in the field of plastic injection molding, has been making waves in the industry with its cutting-edge technology and innovative solutions. With a relentless commitment to quality and customer satisfaction, Precision Injection has established itself as a trusted name in the market.Founded over 20 years ago, Precision Injection has continually evolved and adapted to meet the ever-changing demands of the industry. The company's state-of-the-art facilities are equipped with the latest machinery and equipment, allowing them to produce high-quality products with exceptional precision and accuracy.One of Precision Injection's core strengths lies in its ability to work closely with clients to develop customized solutions that meet their specific needs. The company's team of experienced engineers and designers are dedicated to finding creative and cost-effective ways to bring their clients' visions to life.Precision Injection's commitment to excellence is reflected in its stringent quality control measures. Every product that leaves the facility undergoes rigorous testing to ensure that it meets the highest standards of quality and performance. This attention to detail has earned the company a reputation for reliability and consistency, making them the go-to choice for clients across a wide range of industries.In addition to their dedication to quality, Precision Injection is also committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing processes and materials, minimizing their carbon footprint and impact on the environment. This focus on sustainability has not only earned the company the respect of its peers but has also resonated with environmentally conscious clients looking for a responsible manufacturing partner.Precision Injection's wide range of capabilities extends to various industries, including automotive, medical, consumer goods, and more. The company's expertise in producing complex and intricate parts has made them a valuable partner for clients with high-performance requirements. From small, intricate components to large, durable parts, Precision Injection has the capacity and expertise to handle projects of all sizes and complexities.The company's success can be attributed to its relentless pursuit of innovation and improvement. Precision Injection continually invests in research and development, exploring new materials, processes, and technologies to stay ahead of the curve. This forward-thinking approach has enabled the company to remain at the forefront of the industry and anticipate and meet the evolving needs of its clients.In recognition of its excellence, Precision Injection has received several accolades and certifications, further solidifying its reputation as a leader in the field. The company's dedication to the highest standards of quality and service has earned it the trust and loyalty of a diverse and prestigious client base.Looking to the future, Precision Injection remains committed to its core values of quality, innovation, and customer satisfaction. With a focus on continuous improvement and a keen eye on emerging trends and technologies, the company is poised to continue its upward trajectory and maintain its position as a top-tier manufacturer in the industry.In conclusion, Precision Injection stands as a shining example of excellence in the field of plastic injection molding. With its commitment to quality, innovation, and sustainability, the company has carved out a niche for itself as a trusted and reliable partner for clients across various industries. As they continue to push the boundaries of what is possible in plastic injection molding, Precision Injection is undoubtedly a force to be reckoned with in the industry.

Aluminum CNC Turning Parts for Electroplating - A Complete Guide

Metal manufacturing company, based in [location], has recently announced the launch of their new product, Electroplating Aluminum CNC turning parts. This innovative product has been developed to meet the growing demand for high-quality aluminum parts in various industries such as automotive, aerospace, and electronics.The Electroplating Aluminum CNC turning parts are designed to be versatile and durable, making them suitable for a wide range of applications. With their high precision and tight tolerances, these parts are capable of meeting the strict requirements of modern manufacturing processes. The company has invested in state-of-the-art CNC turning machines to ensure the highest quality and consistency in the production of these parts.In addition to their exceptional quality, the Electroplating Aluminum CNC turning parts also offer excellent corrosion resistance and a sleek, attractive finish. This makes them ideal for use in outdoor, marine, and other harsh environments where protection against corrosion is essential. The electroplating process in which the parts undergo enhances their surface hardness and wear resistance, making them suitable for long-term use.The company's decision to develop and manufacture Electroplating Aluminum CNC turning parts comes as a response to the increasing demand for such products in both domestic and international markets. With the rising trend towards lightweight and high-performance materials in various industries, the company saw an opportunity to expand its product offering and cater to the evolving needs of its customers.Furthermore, the company's extensive experience and expertise in metal manufacturing have allowed them to develop and produce Electroplating Aluminum CNC turning parts that meet the highest industry standards. Their dedicated team of engineers and technicians has worked tirelessly to ensure that these parts deliver exceptional performance and reliability in the most demanding applications.The development and launch of these Electroplating Aluminum CNC turning parts are a testament to the company's commitment to innovation and customer satisfaction. They have continuously invested in research and development to bring cutting-edge products to the market, and the new parts are a reflection of their dedication to staying at the forefront of the industry."We are thrilled to introduce our new Electroplating Aluminum CNC turning parts to the market," said the company's spokesperson. "We believe that these parts will set a new standard for quality and performance in the industry, and we are confident that they will meet the diverse needs of our customers. With our advanced manufacturing capabilities and stringent quality control processes, we are well-positioned to deliver these parts to customers around the world."The Electroplating Aluminum CNC turning parts are now available for purchase, and the company is ready to fulfill orders from customers across different industries. With their strong commitment to customer satisfaction and their ability to tailor solutions to specific requirements, the company is confident that these parts will be well-received in the market.As the demand for high-quality aluminum parts continues to grow, the launch of the Electroplating Aluminum CNC turning parts represents a significant milestone for the company and reinforces its position as a leading provider of metal manufacturing solutions. With their dedication to innovation and excellence, the company is poised to make a lasting impact in the industry and meet the evolving needs of its customers.

Precision Machining of Aerospace Components: A Vital Process for Aerospace Industry

In the world of aerospace engineering, precision and accuracy are of utmost importance. The demand for high-quality aerospace components has soared in recent years, and the company {} has been at the forefront of delivering top-notch machining solutions in this industry. With their state-of-the-art technology and skilled workforce, they have remained a leading player in the market.Established in {}, {} has built a strong reputation for providing machining solutions for aerospace components. They have a deep understanding of the aerospace industry's unique requirements and have tailored their services to meet the stringent standards set by this sector. The company's commitment to excellence and continuous innovation has allowed them to maintain their position as a trusted partner for aerospace manufacturers worldwide.Their expertise lies in CNC machining, turning, milling, and grinding of aerospace components. The company's manufacturing facilities are equipped with advanced machining tools and equipment, allowing them to produce complex and high-precision parts with tight tolerances. They work with a wide range of materials, including aluminum, titanium, stainless steel, and composites, to meet the diverse needs of their aerospace clients.One of the key strengths of {} is their team of skilled machinists and engineers. They have a deep understanding of the aerospace industry's unique requirements and are well-versed in the latest machining techniques and technologies. This expertise enables them to tackle complex machining challenges and deliver superior quality components that meet the highest standards of the aerospace industry.The company's commitment to quality is reflected in their adherence to stringent quality control measures. They have implemented rigorous inspection processes at every stage of the manufacturing process to ensure that the final products meet the required specifications. Additionally, {} is certified to AS9100 and ISO 9001 standards, underscoring their dedication to delivering aerospace components of the highest quality.In addition to their machining capabilities, {} also offers value-added services such as assembly, testing, and logistical support. This end-to-end approach allows them to serve as a comprehensive solutions provider for aerospace manufacturers, contributing to streamlining their supply chain and reducing lead times.Looking to the future, {} continues to invest in cutting-edge technologies and continuous improvement initiatives to further enhance their capabilities. They are constantly exploring new avenues for innovation and expanding their service offerings to meet the evolving needs of the aerospace industry.As the aerospace industry continues to grow and advance, the demand for high-quality machining solutions will only increase. {} is well-positioned to continue serving as a trusted partner for aerospace manufacturers, delivering top-notch components that meet the strict requirements of this industry. With their unwavering commitment to excellence and continuous pursuit of innovation, {} is poised to remain a leading player in the aerospace machining sector for years to come.

Top Laser Cutting Parts Manufacturers in China Offering Quality Products and Services

China Laser Cutting Parts Manufacturers has recently announced the expansion of their product line to meet the increasing demand for high-quality laser cutting parts. The company has been a leading manufacturer in the industry for over a decade, and their latest move is set to solidify their position as a top provider of laser cutting solutions.With a focus on precision and efficiency, China Laser Cutting Parts Manufacturers has built a reputation for delivering superior products that meet the diverse needs of their clients. Their state-of-the-art facilities and advanced technology allow them to produce a wide range of laser cutting parts, including but not limited to metal sheets, tubes, and pipes.The company's commitment to innovation and continuous improvement has enabled them to stay at the forefront of the industry. By investing in the latest equipment and employing a team of highly skilled technicians, China Laser Cutting Parts Manufacturers consistently delivers products that exceed industry standards. This has earned them a loyal customer base and solidified their reputation as a trusted supplier in the market.In response to the growing demand for precision-cut parts, China Laser Cutting Parts Manufacturers has expanded their production capabilities to ensure they can meet the needs of their clients. This expansion will enable them to produce a greater volume of parts without compromising on quality, further strengthening their position as an industry leader.Furthermore, China Laser Cutting Parts Manufacturers understands the importance of sustainability and environmental responsibility in today's business landscape. They have implemented sustainable practices in their production processes to minimize waste and reduce their carbon footprint. This demonstrates their commitment to operating in an environmentally friendly manner while providing high-quality products to their clients.In addition to their focus on product quality and sustainability, China Laser Cutting Parts Manufacturers places a high priority on customer service. They work closely with their clients to understand their specific needs and provide customized solutions to meet their requirements. This approach has enabled them to build strong and lasting relationships with their customers, further solidifying their position as a trusted partner in the industry.The company's dedication to excellence and customer satisfaction has earned them a solid reputation in the market. They have received numerous accolades for their outstanding performance and have been recognized as a top supplier of laser cutting parts. This is a testament to their unwavering commitment to delivering the best products and services to their clients.Looking ahead, China Laser Cutting Parts Manufacturers is poised to continue their growth and success in the industry. With their expanded product line and commitment to excellence, they are well-positioned to meet the evolving needs of their clients and remain at the forefront of the laser cutting parts manufacturing sector.In conclusion, China Laser Cutting Parts Manufacturers' recent expansion is a testament to their dedication to meeting the growing demand for high-quality laser cutting parts. With their focus on precision, sustainability, and customer satisfaction, they are well-positioned to maintain their position as a top supplier in the industry. Their commitment to excellence and continuous improvement ensures that they will continue to be a trusted partner for their clients' laser cutting needs.