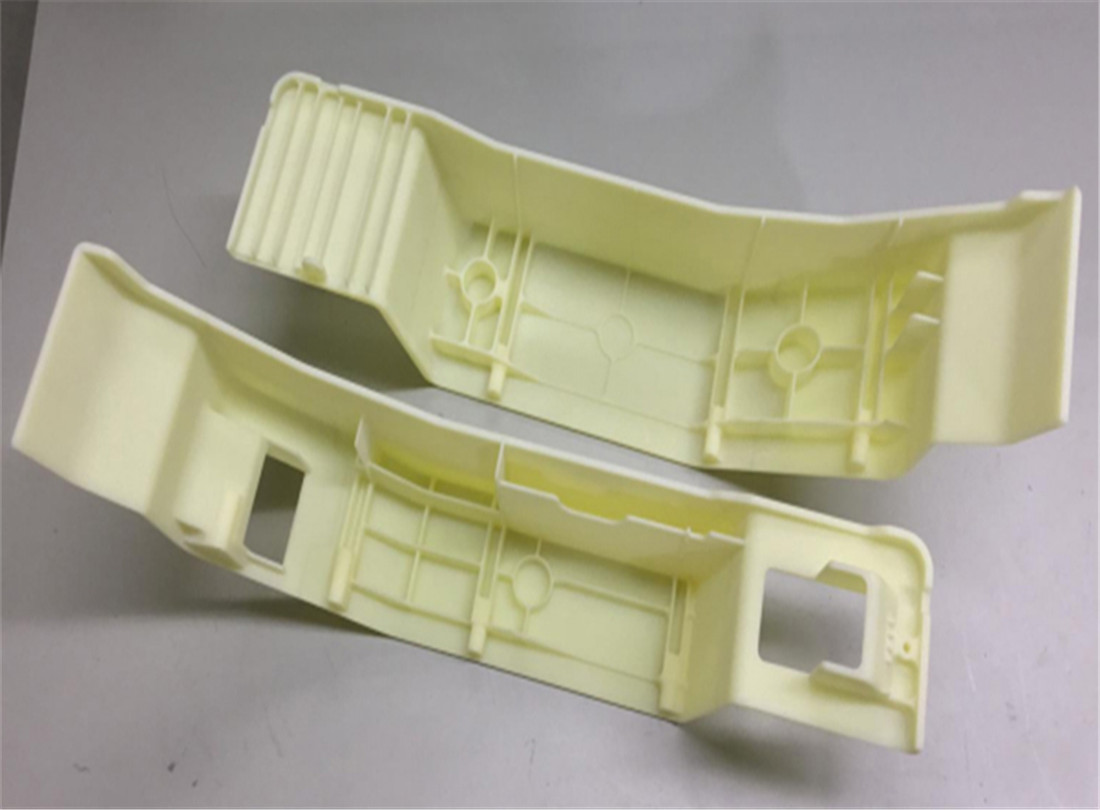

High-Quality Plastic Mold Components for Various Industries

By:Admin

The company's extensive product line includes a variety of mold bases, mold components, hot runner systems, and other essential components for plastic injection molding. These products are designed to meet the demanding requirements of the industry and are built to deliver exceptional performance and durability.

One of the key strengths of Plastic Mold Components is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and bring cutting-edge solutions to its customers. This dedication to innovation has enabled the company to develop a range of patented technologies and proprietary products that have set new standards in the industry.

In addition to its focus on innovation, Plastic Mold Components is also dedicated to providing superior customer service and support. The company's team of skilled and experienced professionals is committed to working closely with customers to understand their specific needs and provide tailored solutions. Whether it's assisting with product selection, offering technical support, or providing onsite assistance, the team at Plastic Mold Components is always ready to go the extra mile to ensure customer satisfaction.

Furthermore, the company's commitment to quality is evident in its rigorous quality control processes and adherence to industry standards. All products undergo strict testing and inspection to ensure they meet the highest standards for performance, reliability, and safety. This dedication to quality has earned Plastic Mold Components a reputation for excellence and reliability in the industry.

Beyond its commitment to quality and innovation, Plastic Mold Components also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing its environmental footprint and continuously seeks ways to reduce waste, conserve resources, and operate in an environmentally friendly manner. This commitment to sustainability is not only reflected in the company's products but also in its operations and business practices.

Looking ahead, Plastic Mold Components is poised for continued growth and success in the industry. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the plastic molding industry and continue to drive progress and excellence.

In conclusion, Plastic Mold Components stands as a trusted partner and supplier for companies in the plastic molding industry. With a commitment to quality, innovation, and customer satisfaction, the company continues to deliver cutting-edge solutions and set new standards in the industry. As the company looks to the future, it remains dedicated to driving progress, sustainability, and success in the industry.

Company News & Blog

High-quality aerospace CNC machining services for precision parts

Aerospace CNC Machining, the leading provider of precision machining for the aerospace industry, has established itself as a trusted partner for companies seeking high-quality components for their aircraft and space vehicles. With a strong commitment to excellence and a dedication to customer satisfaction, Aerospace CNC Machining has become a key player in the aerospace manufacturing industry.The company, based in [location], has a state-of-the-art facility equipped with the latest CNC machining technology. This allows the company to produce complex and intricate components with the highest level of precision and accuracy. Aerospace CNC Machining's team of highly skilled engineers and machinists are experts in working with a wide range of materials, including aluminum, titanium, and stainless steel, ensuring that they can meet the specific needs of their aerospace clients.One of the key factors that sets Aerospace CNC Machining apart from its competitors is its unwavering commitment to quality. The company adheres to stringent quality control measures at every stage of the manufacturing process, from initial design to final inspection. This ensures that each component produced by Aerospace CNC Machining meets the strict standards and specifications required by the aerospace industry.In addition to its focus on quality, Aerospace CNC Machining also prioritizes efficiency and timely delivery. The company understands the fast-paced nature of the aerospace industry and works diligently to meet tight deadlines without sacrificing quality. This has earned Aerospace CNC Machining a reputation for reliability and dependability among its clients.Aerospace CNC Machining's dedication to excellence has not gone unnoticed. The company has been recognized with several industry awards for its outstanding performance and contributions to the aerospace manufacturing sector. These accolades serve as a testament to Aerospace CNC Machining's commitment to being a leader in the industry.Aerospace CNC Machining's expertise extends to a wide range of aerospace components, including aircraft engine parts, landing gear components, structural fittings, and much more. The company has the capability to handle both small-scale and large-scale production runs, making it a versatile partner for aerospace manufacturers of all sizes.Aerospace CNC Machining's customer-centric approach is another key aspect of its success. The company works closely with each client to understand their specific needs and requirements, and then develops tailored solutions to meet those needs. This personalized approach has helped Aerospace CNC Machining build strong, long-lasting relationships with its clients, many of whom consider the company a trusted partner in their supply chain.Looking ahead, Aerospace CNC Machining is focused on continuing to expand its capabilities and offerings in order to better serve the evolving needs of the aerospace industry. The company invests in ongoing research and development to stay at the forefront of technological advancements and industry trends. This commitment to innovation ensures that Aerospace CNC Machining remains a leader in the aerospace manufacturing sector for years to come.As the aerospace industry continues to grow and evolve, the demand for high-quality precision components will only increase. Aerospace CNC Machining is well-positioned to meet this demand and continue to be a valued partner for aerospace manufacturers around the world. With its relentless focus on quality, efficiency, and customer satisfaction, Aerospace CNC Machining has established itself as a driving force in the aerospace manufacturing industry and is poised for continued success in the future.

- The Importance of Plastic Injection Mold Tooling for Manufacturing Industry

The demand for plastic injection mold tooling has been on the rise in recent years, as more industries recognize the numerous benefits it offers. From automotive and medical to aerospace and consumer goods, plastic injection mold tooling plays a crucial role in manufacturing high-quality plastic parts and products.{Company Name}, a leading provider of plastic injection mold tooling, has been at the forefront of this industry for over 25 years. With a strong commitment to innovation and quality, {Company Name} has established itself as a trusted partner for businesses looking to enhance their plastic injection molding capabilities.The company specializes in designing and manufacturing high-precision molds for a wide range of applications. Whether it's a complex automotive component or a delicate medical device, {Company Name} has the expertise and technology to deliver custom mold tooling solutions that meet the highest performance standards.One of the key advantages of choosing {Company Name} for plastic injection mold tooling is their state-of-the-art facility equipped with the latest machinery and technology. This allows the company to handle even the most intricate mold designs with precision and efficiency, ensuring that the final products meet or exceed customer expectations.In addition to their technical capabilities, {Company Name} is known for its commitment to customer satisfaction. The company works closely with each client to understand their specific needs and requirements, and then develops a tailored mold tooling solution that aligns with their goals and budget.The team at {Company Name} brings a wealth of experience and expertise to every project, leveraging their industry knowledge to provide valuable insights and recommendations. From material selection and mold design to production processes and quality control, {Company Name} is dedicated to delivering comprehensive support at every stage of the mold tooling process.Furthermore, {Company Name} prioritizes continuous improvement and innovation, investing in research and development to stay ahead of industry trends and technological advancements. This proactive approach enables the company to offer cutting-edge mold tooling solutions that enhance the performance and efficiency of plastic injection molding operations.In recent years, {Company Name} has expanded its capabilities to offer a broader range of services, including mold maintenance, repair, and modification. This comprehensive approach allows customers to rely on {Company Name} not only for initial mold tooling, but also for ongoing support to ensure the longevity and optimal performance of their molds.The quality and reliability of {Company Name}'s plastic injection mold tooling have earned the company a stellar reputation in the industry. As a result, {Company Name} has formed long-term partnerships with leading manufacturers across various sectors, establishing itself as a trusted and preferred supplier for their mold tooling needs.Looking ahead, {Company Name} remains committed to driving innovation and delivering exceptional value to its customers. The company continues to invest in advanced technology and talent, and is dedicated to expanding its capabilities to meet the evolving needs of the plastic injection molding industry.In conclusion, the demand for plastic injection mold tooling is higher than ever, and {Company Name} is well-positioned to meet this demand with its unparalleled expertise, technology, and customer-centric approach. As the industry continues to grow and evolve, businesses can rely on {Company Name} as a strategic partner for all their plastic injection mold tooling needs.

Expert Guide to Aluminum Sheet Metal Punch Processing Fabrication

Aluminum Sheet Metal Punch Processing Fabrication on the RiseWith the increasing demand for precision metal fabrication, the aluminum sheet metal punch processing industry has been experiencing significant growth. [Company Name], a leading provider of metal fabrication solutions, has been at the forefront of this trend, excelling in aluminum sheet metal punch processing fabrication.As a prominent player in the industry, [Company Name] has built a strong reputation for delivering high-quality metal products and offering reliable fabrication services. The company utilizes advanced technologies and state-of-the-art equipment to ensure precision and efficiency in the aluminum sheet metal punch processing fabrication process.The aluminum sheet metal punch processing fabrication involves the use of specialized machinery to create precise holes, cutouts, and other shapes in aluminum sheets. This process is critical in various industries, including automotive, aerospace, construction, and electronics, where metal components are an integral part of the manufacturing process.One of the key advantages of aluminum sheet metal punch processing fabrication is its ability to produce complex parts with tight tolerances. This has made it an essential service for companies seeking to develop intricate and customized components for their products.[Company Name] offers a wide range of aluminum sheet metal punch processing fabrication services, catering to the diverse needs of its clients. From simple punching and cutting to complex forming and bending, the company is capable of accommodating various design specifications and production requirements.The company's team of skilled engineers and technicians are well-versed in handling different types of aluminum alloys, ensuring that the fabricated products meet the highest standards of quality and durability. Additionally, [Company Name] places great emphasis on adhering to strict quality control measures throughout the fabrication process, guaranteeing the reliability and performance of the final products.In line with environmental sustainability, [Company Name] is committed to implementing eco-friendly practices in its aluminum sheet metal punch processing fabrication operations. By optimizing energy efficiency and reducing waste, the company aims to minimize its environmental footprint while delivering exceptional metal fabrication solutions.Furthermore, [Company Name] prioritizes customer satisfaction by providing personalized design assistance, rapid prototyping, and on-time delivery of fabricated aluminum sheet metal products. The company's dedication to meeting the unique needs of its clients has resulted in long-term partnerships with numerous businesses across various industries.As the demand for aluminum sheet metal punch processing fabrication continues to grow, [Company Name] remains committed to investing in advanced technologies and expanding its capabilities to meet the evolving requirements of the market. By staying at the forefront of innovation, the company anticipates sustaining its leadership in the metal fabrication industry and delivering unparalleled solutions to its clients.In conclusion, the aluminum sheet metal punch processing fabrication industry is experiencing substantial growth, driven by the increasing demand for precision metal components in various sectors. [Company Name], with its expertise in aluminum sheet metal punch processing fabrication, is well-positioned to meet this demand while upholding the highest standards of quality, innovation, and customer service. With its dedication to excellence and continuous improvement, the company is poised to remain a key player in the metal fabrication industry for years to come.

Top Clear Plastic Molding Techniques for Your Project

Clear Plastic Molding Company, a leading provider of high-quality plastic molding solutions, has been making significant strides in the industry. With a commitment to innovation and excellence, the company has built a strong reputation for delivering top-notch products to its clients. Clear Plastic Molding Company has been in the business for over two decades and has established itself as a trusted partner for businesses in need of custom plastic molding solutions.The company specializes in clear plastic molding, offering a wide range of services including injection molding, blow molding, and thermoforming. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing them to produce complex and intricate plastic parts with precision and efficiency. Whether it's a small run of prototypes or a large-scale production, Clear Plastic Molding Company has the capabilities to meet the needs of their clients.One of the key strengths of Clear Plastic Molding Company is its dedication to quality. The company adheres to strict quality control measures at every step of the manufacturing process to ensure that the final products meet the highest standards. From raw material sourcing to final inspection, Clear Plastic Molding Company goes above and beyond to deliver products that are durable, reliable, and visually appealing.In addition to quality, Clear Plastic Molding Company also prioritizes customer satisfaction. The company has a team of experienced engineers and designers who work closely with clients to understand their specific requirements and deliver custom solutions that meet their needs. From concept and design to production and delivery, Clear Plastic Molding Company provides end-to-end support to its clients, ensuring a smooth and hassle-free experience.Furthermore, Clear Plastic Molding Company is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes recyclable materials whenever possible, reducing its carbon footprint and contributing to a more sustainable future. Clear Plastic Molding Company understands the importance of environmental conservation and strives to minimize its impact on the planet.Clear Plastic Molding Company has a diverse client base, serving a wide range of industries including automotive, medical, consumer goods, and electronics. The company's ability to adapt to the unique requirements of each industry has earned it a favorable reputation among its clients. Whether it's producing intricate medical device components or durable automotive parts, Clear Plastic Molding Company has the expertise and resources to deliver exceptional results.Looking ahead, Clear Plastic Molding Company is focused on further expanding its capabilities and enhancing its offerings. The company is continuously investing in research and development to stay at the forefront of innovation in plastic molding technology. Additionally, Clear Plastic Molding Company is exploring new opportunities for growth, including potential partnerships and collaborations that will enable it to reach new markets and serve a broader range of clients.In conclusion, Clear Plastic Molding Company is a leading provider of clear plastic molding solutions, known for its commitment to quality, customer satisfaction, and sustainability. With a focus on innovation and excellence, the company has established itself as a trusted partner for businesses in need of custom plastic molding services. As the industry continues to evolve, Clear Plastic Molding Company is well-positioned to thrive and further solidify its position as a top-tier provider of plastic molding solutions.

High-Quality Plastic Injection Tooling: What You Need to Know

Plastic Injection Tooling, a key component in the manufacturing process for a wide range of products, is a critical part of the production line for many companies. It is essential for creating high-quality, precision-engineered plastic components that are used in various industries such as automotive, aerospace, medical, consumer goods, and more. With the market demand for plastic injection tooling on the rise, it's important for companies to have access to reliable and efficient tools that can meet their production needs.{Company Name} is a leading provider of plastic injection tooling solutions, offering a wide range of services to help companies optimize their production processes. From design and engineering to prototype development and mass production, {Company Name} delivers high-quality, cost-effective solutions to meet the unique needs of each customer. With a team of experienced engineers and state-of-the-art facilities, {Company Name} is committed to providing top-notch plastic injection tooling that exceeds customer expectations.One of the key advantages of {Company Name}'s plastic injection tooling solutions is their ability to work with a variety of materials, including traditional thermoplastics, engineering resins, and high-performance materials. This flexibility allows customers to choose the best material for their specific application, whether it's for a high-stress automotive component or a delicate medical device. {Company Name} also offers expertise in designing complex tooling systems that can produce intricate parts with tight tolerances, giving customers the confidence that their products will meet the highest quality standards.In addition to their technical expertise, {Company Name} prides itself on its commitment to customer service and satisfaction. Their team works closely with each customer to understand their unique requirements and objectives, providing personalized solutions that meet their needs and budget. Whether it's a small prototype run or a large-scale production project, {Company Name} is dedicated to delivering the right plastic injection tooling solution on time and within budget.{Company Name} has also invested in cutting-edge technology and equipment to ensure that they stay at the forefront of the industry. Their state-of-the-art manufacturing facilities are equipped with the latest CNC machines, EDM equipment, and mold flow analysis software, allowing them to produce high-quality tooling with precision and efficiency. This technology, combined with their team's expertise, enables {Company Name} to deliver top-notch plastic injection tooling solutions that help their customers stay competitive in the marketplace.As the demand for plastic injection tooling continues to grow, {Company Name} remains committed to innovation and continuous improvement. They are constantly exploring new materials, technologies, and processes to enhance their capabilities and deliver better value to their customers. By staying ahead of industry trends and investing in the latest tools and equipment, {Company Name} aims to remain a trusted partner for companies looking for reliable and efficient plastic injection tooling solutions.Overall, the continued success of {Company Name} is a testament to their dedication to quality, innovation, and customer satisfaction. As the demand for plastic injection tooling continues to rise, companies can rely on {Company Name} to deliver the high-quality, cost-effective solutions they need to stay competitive in the marketplace. With their expertise, state-of-the-art facilities, and commitment to excellence, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the plastic injection tooling market.

Top 5 Factors to Consider When Choosing an Injection Moulding Die

Injection Moulding Die: Revolutionizing the Manufacturing IndustryWith the ever-growing demand for high-quality plastic products in various industries, the manufacturing sector is witnessing a surge in the use of injection moulding dies. These dies have become an indispensable tool in the production of a wide range of plastic components, from automotive parts to consumer goods. One company that has been at the forefront of this revolution is {}, a leading manufacturer of injection moulding dies.Established in {}, {} has been providing innovative solutions to their clients in the manufacturing industry for over {} years. Specializing in the design and fabrication of precision moulds, the company has earned a reputation for delivering high-quality products and exceptional customer service.The injection moulding process involves the use of a moulding die, which is a tool that is used to shape molten plastic into a desired form. The die is comprised of two main parts: the stationary side, known as the cavity, and the moving side, known as the core. When the molten plastic is injected into the die, it is subjected to high pressure, causing it to take the shape of the mould. Once the plastic has cooled and solidified, the die is opened, and the finished product is ejected.{} has been at the forefront of developing advanced injection moulding dies that are capable of producing complex and intricate plastic components with high precision and efficiency. The company's team of skilled engineers and technicians work closely with their clients to understand their specific requirements and provide customized solutions that meet their production needs.The injection moulding dies manufactured by {} are designed to enhance the overall manufacturing process, improving productivity and reducing the production cycle time. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce high-quality moulds with tight tolerances and consistent performance. This has enabled {} to serve a diverse range of industries, including automotive, electronics, medical, and consumer goods.One of the key advantages of using injection moulding dies from {} is the ability to produce large volumes of plastic components with remarkable precision and repeatability. This is particularly beneficial for manufacturers who require consistent quality and uniformity in their products. The company's commitment to continuous innovation and improvement has positioned them as a trusted partner for companies looking to enhance their manufacturing capabilities.In addition to their cutting-edge injection moulding dies, {} also offers comprehensive support services to their clients, including mould maintenance, repair, and refurbishment. This ensures that their clients can maximize the lifespan of their moulds and minimize downtime, ultimately optimizing their production operations.As the demand for high-quality plastic products continues to rise, the role of injection moulding dies in the manufacturing industry becomes increasingly crucial. {} has demonstrated their ability to stay ahead of the curve by delivering top-notch moulds that align with the evolving needs of the industry. By combining their technical expertise, manufacturing capabilities, and customer-oriented approach, the company has established itself as a leader in the injection moulding die market.Looking ahead, {} remains committed to pushing the boundaries of innovation and setting new standards for excellence in the manufacturing sector. The company's dedication to delivering exceptional products and services positions them as a trusted partner for manufacturers seeking to optimize their production processes and stay competitive in the global market.In conclusion, injection moulding dies have undoubtedly revolutionized the manufacturing industry, and {} has been at the forefront of this transformation. With their advanced mould design and fabrication capabilities, the company continues to drive the industry forward, empowering manufacturers to achieve greater efficiency and precision in their production operations.

Benefits of Injection Molded Plastics for Clear Products

Clear Injection Molded Plastics has been making waves in the plastics industry with their innovative and high-quality products. The company, which was established in 1995, has quickly become a leader in the field of injection molded plastics. Their commitment to providing the highest level of service and quality has made them a go-to supplier for businesses in a wide range of industries.Clear Injection Molded Plastics specializes in creating custom plastic components for a variety of applications. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to produce high-quality, precision-engineered products. From medical devices to automotive components, Clear Injection Molded Plastics has the capabilities to meet the needs of any customer.One of the company's most notable achievements is their development of clear injection molded plastics. This groundbreaking technology has opened up a world of possibilities for businesses looking for transparent or translucent plastic components. Clear plastics are in high demand across numerous industries, including medical, consumer goods, and electronics. Clear Injection Molded Plastics' ability to produce these components with exceptional clarity and precision has set them apart from their competitors.In addition to their commitment to quality and innovation, Clear Injection Molded Plastics also places a strong emphasis on sustainability. They have implemented several environmentally friendly practices in their manufacturing process, such as recycling and using eco-friendly materials. Their dedication to reducing their environmental impact has not gone unnoticed, and they have gained a reputation as a responsible and ethical supplier.Clear Injection Molded Plastics' success can be attributed to their team of highly skilled and experienced professionals. From design and engineering to manufacturing and quality control, every aspect of the production process is handled by knowledgeable experts. This ensures that every product that leaves their facility meets the highest standards of quality and performance.Furthermore, Clear Injection Molded Plastics is committed to providing exceptional customer service. They work closely with their clients to understand their specific needs and requirements, and then tailor their products and services to meet those needs. This level of personalized attention has earned them a loyal customer base and has helped them build long-lasting partnerships with businesses of all sizes.Looking to the future, Clear Injection Molded Plastics is poised for continued growth and success. Their investment in cutting-edge technology and their dedication to innovation will undoubtedly keep them at the forefront of the plastics industry. As the demand for high-quality, clear injection molded plastics continues to rise, Clear Injection Molded Plastics is well-positioned to capitalize on this trend and expand their market presence.In conclusion, Clear Injection Molded Plastics has established itself as a leader in the plastics industry through its commitment to quality, innovation, and sustainability. With their advanced capabilities, skilled team, and dedication to customer service, they have set themselves apart as a top supplier of custom plastic components. As they continue to grow and evolve, Clear Injection Molded Plastics is poised to remain a driving force in the industry for years to come.

How Injection Moulding Works: A Comprehensive Guide

Injection Moulder Celebrates Continued Success with Expansion and InnovationWith over 20 years of experience in the plastic injection molding industry, Injection Moulder has established a strong reputation for providing high-quality precision parts for a variety of industries. The company has recently celebrated its continued success with the expansion of its facilities and the introduction of innovative new technologies.Injection Moulder, based in [Location], has built a solid foundation in the plastic injection molding industry with its dedication to delivering top-notch products and exceptional customer service. Specializing in custom injection molding, the company has served a wide range of industries including automotive, medical, consumer products, and industrial manufacturing.The company's commitment to quality and innovation has been evident in its recent expansion efforts. Injection Moulder has invested in a state-of-the-art production facility that has allowed for increased capacity and improved efficiency. This expansion has enabled the company to better serve its growing customer base and to take on more complex and demanding projects.In addition to expanding its facilities, Injection Moulder has also focused on incorporating innovative technologies into its production processes. The company has adopted the latest advancements in injection molding equipment and automation systems, allowing for greater precision, consistency, and speed in manufacturing."We are thrilled to announce the expansion of our facilities and the integration of advanced technologies into our production processes," said [Spokesperson], CEO of Injection Moulder. "These developments have been instrumental in furthering our commitment to delivering high-quality products and exceeding the expectations of our customers."Injection Moulder's dedication to innovation and continuous improvement has not gone unnoticed. The company has received accolades for its exceptional performance and has been recognized as a reliable and trusted partner in the plastic injection molding industry.In addition to its expansion and technological advancements, Injection Moulder has also made strides in sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, including the use of recycled materials and energy-efficient equipment. By prioritizing sustainability, Injection Moulder aims to reduce its environmental impact and contribute to a cleaner and healthier planet.Furthermore, Injection Moulder has placed a strong emphasis on workforce development and employee satisfaction. The company has invested in training programs and professional development opportunities for its employees, fostering a culture of continuous learning and growth. Injection Moulder's team of skilled and dedicated professionals is crucial to the company's success and plays a significant role in delivering exceptional products and services.Looking ahead, Injection Moulder remains committed to staying at the forefront of the plastic injection molding industry. The company is dedicated to exploring new opportunities for growth and innovation, while maintaining its focus on quality, customer satisfaction, and sustainability."We are excited about the future of Injection Moulder and the possibilities that lie ahead," [Spokesperson] added. "As we continue to invest in our capabilities and push the boundaries of what is possible in plastic injection molding, we are confident that Injection Moulder will remain a leader in the industry for years to come."With its expansion, technological advancements, and commitment to excellence, Injection Moulder has solidified its position as a trusted and reliable partner for businesses seeking high-quality plastic injection molding solutions. The company's dedication to innovation, sustainability, and customer satisfaction sets it apart in the industry and paves the way for continued success in the years to come.

Diverse Metal Fabrication: A Comprehensive Guide to Superior Metalwork

The art of metal fabrication has been revolutionized in recent years thanks to the innovative techniques developed by (company name). By using state-of-the-art technology and a highly skilled workforce, the company has become a leader in the complex metal fabrication industry.Founded in (year), (company name) has quickly gained a reputation for its precision and attention to detail in every project. Their facility, located in (location), is equipped with the latest machinery and tools, allowing them to take on a wide range of complex metal fabrication projects.One of the key features of (company name) is its ability to work with a variety of metals, including stainless steel, aluminum, and titanium. This versatility has allowed them to cater to a diverse clientele, ranging from the aerospace industry to the automotive sector.One of the most notable aspects of (company name) is its commitment to quality control. Every step of the fabrication process is carefully monitored to ensure that the final product meets the highest standards. This dedication to excellence has earned them the trust of their clients, who rely on them to deliver top-notch products every time.In addition to their technical prowess, (company name) also prides itself on its ability to provide customized solutions for its clients. Whether it's a one-of-a-kind prototype or a large-scale production run, the team at (company name) is dedicated to fulfilling the unique needs of each customer.Furthermore, their team of experienced engineers and designers work closely with clients from the initial concept to the final product, ensuring that every detail is precisely executed. This collaborative approach has resulted in many successful projects and lasting partnerships with numerous clients.One of the most recent projects undertaken by (company name) was the fabrication of a complex metal component for a leading aerospace company. The client required a high-strength, lightweight component for their new aircraft, and (company name) was able to deliver a flawless solution that exceeded their expectations.The success of this project has further solidified (company name)'s reputation as a premier provider of complex metal fabrication services. With each successful project, they continue to raise the bar for the industry and set new standards for excellence.Looking ahead, (company name) is committed to further expanding its capabilities and enhancing its technological infrastructure. They are constantly investing in the latest equipment and training their workforce to stay ahead of the curve in an ever-evolving industry.In conclusion, (company name) has established itself as a leading force in the complex metal fabrication industry, thanks to its unwavering commitment to quality, precision, and innovation. With a track record of successful projects and a strong focus on customer satisfaction, the company is poised to continue its upward trajectory and remain at the forefront of the industry for years to come.

High-Quality Rubber Gasket for Glass: Find the Best Option for Your Project

[Company Introduction]{Company Name} is a renowned manufacturer of industrial rubber products, with a focus on providing high-quality and durable rubber gaskets for various applications. With decades of experience and a commitment to innovation and customer satisfaction, {Company Name} has established itself as a trusted name in the industry.The company's state-of-the-art manufacturing facilities and cutting-edge technology enable them to produce rubber gaskets that meet the highest standards of quality and performance. {Company Name} serves a wide range of industries, including automotive, aerospace, construction, and marine, providing custom solutions to meet the unique needs of each customer. With a team of skilled engineers and technicians, {Company Name} is able to develop and manufacture rubber gaskets that are tailored to specific requirements, ensuring optimal performance and reliability.In addition to their manufacturing capabilities, {Company Name} is also committed to sustainability and environmental responsibility. The company utilizes eco-friendly materials and processes in their production, minimizing their impact on the environment and ensuring that their products are safe and compliant with industry regulations. {Company Name} is dedicated to delivering exceptional products and service, and their commitment to quality and innovation sets them apart in the industry.[News Content]The demand for high-performance rubber gaskets for glass applications has been on the rise, driven by the increasing need for durable and reliable sealing solutions in various industries. In response to this trend, {Company Name} has introduced a new line of rubber gaskets specifically designed for glass applications, providing superior sealing and protection for a wide range of glass products.The {Company Name} rubber gaskets for glass are engineered to deliver exceptional performance in demanding environments, offering a secure and watertight seal that withstands extreme temperatures, pressure, and environmental conditions. These gaskets are ideal for use in automotive, architectural, marine, and other glass-related applications, providing a reliable and long-lasting sealing solution for both interior and exterior use.One of the key features of {Company Name} rubber gaskets for glass is their versatility and customizability. The company's engineering team works closely with customers to develop gaskets that are tailored to specific glass products, ensuring a perfect fit and optimal sealing performance. Whether it's for automotive windshields, architectural windows, or marine glass enclosures, {Company Name} has the expertise and resources to design and manufacture rubber gaskets that meet the unique requirements of each application.Furthermore, {Company Name} rubber gaskets for glass are manufactured using high-quality materials that are resistant to UV exposure, ozone, and other environmental factors that can degrade conventional gaskets over time. This ensures that the gaskets provide long-term protection and reliability, minimizing maintenance and replacement costs for end users. Additionally, the company's commitment to sustainability means that the gaskets are produced using eco-friendly materials and processes, further enhancing their appeal to environmentally conscious customers.{Company Name}'s dedication to delivering exceptional products and service is reflected in their new line of rubber gaskets for glass. With a focus on quality, performance, and customer satisfaction, the company is poised to meet the growing demand for reliable sealing solutions in the glass industry. By leveraging their expertise and innovation, {Company Name} continues to set the standard for excellence in rubber gaskets, providing customers with the confidence and peace of mind that their glass products are protected by the best sealing solutions available.