The Benefits of Rapid Prototyping CNC Machining for Your Business

By:Admin

[Company name] is a leading provider of rapid prototyping and CNC machining services, offering a wide range of solutions to meet the needs of its clients. With state-of-the-art equipment and a team of experienced professionals, [company name] is able to provide high-quality prototypes and production parts with fast turnaround times.

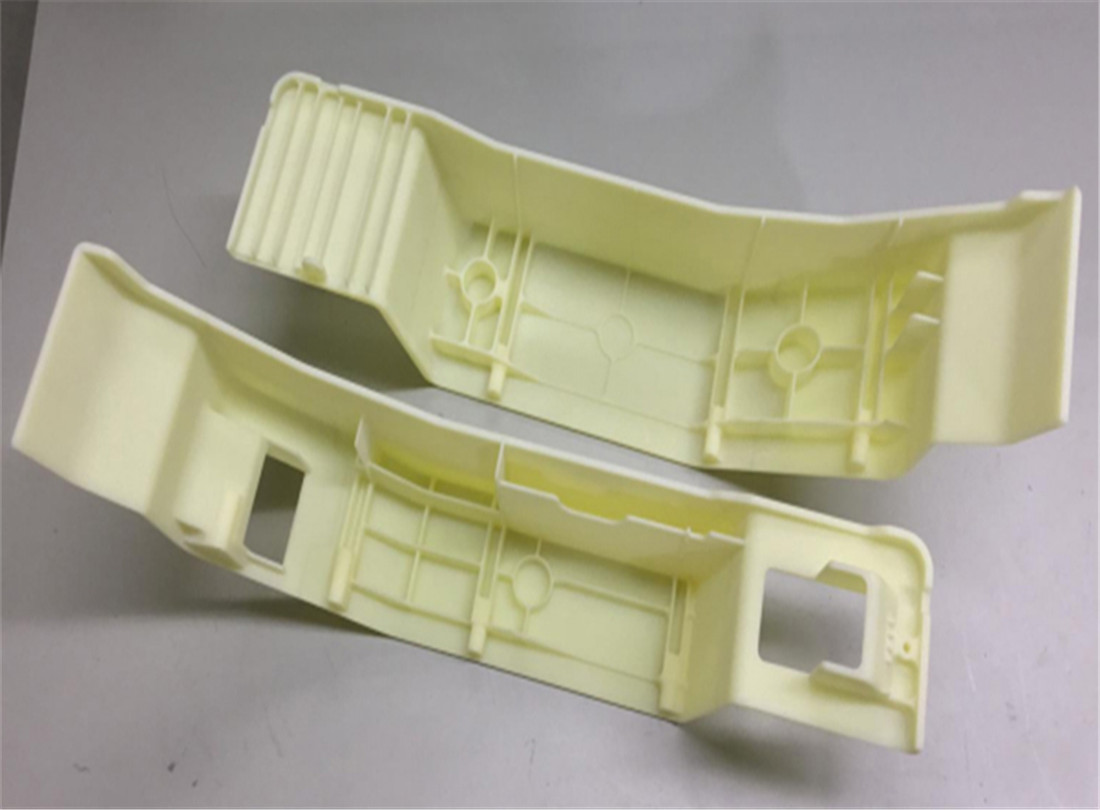

The company’s rapid prototyping services include 3D printing, stereolithography, selective laser sintering, and fused deposition modeling, among others. These technologies allow [company name] to produce accurate and functional prototypes in a matter of hours, helping its clients to reduce their time to market and lower their development costs.

In addition to its rapid prototyping services, [company name] also offers CNC machining, a process that uses computer-controlled machines to produce precision parts from various materials. With a wide range of CNC machining capabilities, including milling, turning, and multi-axis machining, [company name] is able to meet the diverse needs of its clients, from simple prototypes to complex production parts.

One of the key differentiators of [company name] is its ability to work with a wide range of materials, including plastics, metals, and composites. This allows the company to provide its clients with a comprehensive solution for their prototyping and production needs, regardless of the materials they require.

The company’s dedication to quality and customer satisfaction sets it apart from its competitors. With a rigorous quality control process and a commitment to meeting the unique requirements of each project, [company name] has built a reputation for delivering superior products and services to its clients.

Furthermore, [company name] places a strong emphasis on innovation and continuous improvement. The company invests in the latest technologies and equipment to ensure that it remains at the forefront of the industry, allowing it to offer cutting-edge solutions to its clients.

The company’s customer-centric approach is evident in its dedication to providing personalized service and support to each client. Whether a client requires rapid prototyping for a new product design or CNC machining for a production part, [company name] works closely with them to understand their specific needs and deliver a solution that meets or exceeds their expectations.

[Company name] has established itself as a trusted partner for companies in a wide range of industries, including aerospace, automotive, medical, and consumer products. Its ability to deliver high-quality prototypes and production parts with fast turnaround times has made it a preferred choice for many leading companies.

As the manufacturing industry continues to evolve, the demand for rapid prototyping and CNC machining services is expected to grow. With its comprehensive capabilities, dedication to quality, and commitment to innovation, [company name] is well-positioned to meet this demand and continue to be a leader in the industry.

In conclusion, [company name] is a company that is setting new standards in rapid prototyping and CNC machining. With its advanced technologies, diverse capabilities, and customer-centric approach, [company name] is helping its clients to bring their products to market faster and more cost-effectively. As the industry evolves, [company name] remains committed to providing cutting-edge solutions and superior service to its clients, solidifying its position as a trusted partner in the manufacturing industry.

Company News & Blog

High-Quality Plastic Injection Tooling: What You Need to Know

Plastic Injection Tooling, a key component in the manufacturing process for a wide range of products, is a critical part of the production line for many companies. It is essential for creating high-quality, precision-engineered plastic components that are used in various industries such as automotive, aerospace, medical, consumer goods, and more. With the market demand for plastic injection tooling on the rise, it's important for companies to have access to reliable and efficient tools that can meet their production needs.{Company Name} is a leading provider of plastic injection tooling solutions, offering a wide range of services to help companies optimize their production processes. From design and engineering to prototype development and mass production, {Company Name} delivers high-quality, cost-effective solutions to meet the unique needs of each customer. With a team of experienced engineers and state-of-the-art facilities, {Company Name} is committed to providing top-notch plastic injection tooling that exceeds customer expectations.One of the key advantages of {Company Name}'s plastic injection tooling solutions is their ability to work with a variety of materials, including traditional thermoplastics, engineering resins, and high-performance materials. This flexibility allows customers to choose the best material for their specific application, whether it's for a high-stress automotive component or a delicate medical device. {Company Name} also offers expertise in designing complex tooling systems that can produce intricate parts with tight tolerances, giving customers the confidence that their products will meet the highest quality standards.In addition to their technical expertise, {Company Name} prides itself on its commitment to customer service and satisfaction. Their team works closely with each customer to understand their unique requirements and objectives, providing personalized solutions that meet their needs and budget. Whether it's a small prototype run or a large-scale production project, {Company Name} is dedicated to delivering the right plastic injection tooling solution on time and within budget.{Company Name} has also invested in cutting-edge technology and equipment to ensure that they stay at the forefront of the industry. Their state-of-the-art manufacturing facilities are equipped with the latest CNC machines, EDM equipment, and mold flow analysis software, allowing them to produce high-quality tooling with precision and efficiency. This technology, combined with their team's expertise, enables {Company Name} to deliver top-notch plastic injection tooling solutions that help their customers stay competitive in the marketplace.As the demand for plastic injection tooling continues to grow, {Company Name} remains committed to innovation and continuous improvement. They are constantly exploring new materials, technologies, and processes to enhance their capabilities and deliver better value to their customers. By staying ahead of industry trends and investing in the latest tools and equipment, {Company Name} aims to remain a trusted partner for companies looking for reliable and efficient plastic injection tooling solutions.Overall, the continued success of {Company Name} is a testament to their dedication to quality, innovation, and customer satisfaction. As the demand for plastic injection tooling continues to rise, companies can rely on {Company Name} to deliver the high-quality, cost-effective solutions they need to stay competitive in the marketplace. With their expertise, state-of-the-art facilities, and commitment to excellence, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the plastic injection tooling market.

High Precision Milling: The Key to Achieving Perfect Results

High Precision Milling Leads to Enhanced Manufacturing CapabilitiesThe demand for high precision milling solutions has been on the rise in various industries such as aerospace, automotive, and medical devices. This has led to an increasing need for advanced milling technologies that can provide superior accuracy, surface finish, and improved productivity. One company that has been leading the way in this field is {Company Name}. With its state-of-the-art milling technology, the company has been able to meet the evolving needs of its customers and offer high precision milling solutions that are unmatched in the industry. {Company Name} is a leading manufacturer of cutting-edge milling equipment and solutions. The company has a rich history of innovation and has been at the forefront of developing advanced milling technologies that have revolutionized the manufacturing industry. The company’s high precision milling solutions are known for their exceptional accuracy and reliability. {Company Name} utilizes the latest in CNC technology and cutting-edge machining processes to deliver milling solutions that exceed industry standards. One of the key features of {Company Name}'s milling technology is its ability to achieve tight tolerances and high surface finish. This is essential for industries such as aerospace and medical devices, where precision and quality are of utmost importance. {Company Name} has also invested heavily in research and development to continuously improve its milling technology. The company’s team of highly skilled engineers and technologists work tirelessly to innovate and refine their milling solutions, ensuring that they remain at the forefront of technological advancements in the industry. The company's commitment to excellence and innovation has earned it a reputation as a trusted partner for companies looking to enhance their manufacturing capabilities through high precision milling. In addition to its advanced milling technology, {Company Name} also offers a comprehensive range of services to support its customers. This includes expert guidance on selecting the right milling solutions for specific applications, as well as ongoing technical support and maintenance to ensure optimum performance of the equipment. With its cutting-edge technology, commitment to innovation, and dedication to customer support, {Company Name} has established itself as a leader in high precision milling solutions. The company continues to push the boundaries of what is possible in milling technology, providing its customers with the tools they need to succeed in an ever-evolving manufacturing landscape. The growing demand for high precision milling solutions across various industries is a testament to the crucial role that {Company Name} plays in the manufacturing sector. As the industry continues to evolve, companies like {Company Name} will be at the forefront of driving innovation and delivering advanced milling solutions that will shape the future of manufacturing. In conclusion, high precision milling is a critical component of modern manufacturing, and companies like {Company Name} are leading the way in delivering cutting-edge solutions that are redefining the industry. With its advanced technology, commitment to excellence, and comprehensive support services, {Company Name} is well-positioned to continue driving the evolution of high precision milling and empowering its customers to achieve new levels of success in their manufacturing operations.

High-quality CNC Turning Parts Manufacturers in China: A Complete Guide

China CNC Turning Parts Manufacturers, leading provider of precision CNC turning parts, continues to innovate and expand its capabilities to meet the growing demand for high-quality components in the manufacturing industry. With a strong focus on quality, efficiency, and customer satisfaction, the company has established itself as a top choice for businesses seeking reliable CNC turning solutions.As a leading supplier in the industry, China CNC Turning Parts Manufacturers has built a solid reputation for producing high-precision components using advanced CNC turning technology. The company's state-of-the-art manufacturing facilities are equipped with the latest CNC turning machines and inspection tools, allowing them to consistently deliver superior quality parts that meet the most stringent specifications.In addition to their advanced manufacturing capabilities, China CNC Turning Parts Manufacturers also provides comprehensive engineering support to help customers optimize their designs for manufacturability and cost-effectiveness. Their team of experienced engineers works closely with clients to understand their requirements and provide valuable insights to ensure that the final product meets or exceeds expectations.Furthermore, the company has a strong commitment to continuous improvement and investment in new technologies. By staying at the forefront of industry advancements, they are able to offer innovative solutions that drive efficiency and cost savings for their customers. This proactive approach has enabled China CNC Turning Parts Manufacturers to stay ahead of the competition and maintain its position as a trusted partner for businesses across various sectors.In response to the increasing demand for custom CNC turning parts, the company has expanded its production capacity and capabilities. This includes the addition of new CNC turning equipment, as well as the recruitment of skilled machinists and engineers to support their growing operations. With these investments, China CNC Turning Parts Manufacturers is well-positioned to handle large-scale orders and complex projects while maintaining quick turnaround times and competitive pricing.The company's commitment to quality and customer satisfaction is further demonstrated through their stringent quality control processes. Every part manufactured undergoes thorough inspection and testing to ensure that it meets the required specifications and tolerances. This dedication to quality has earned China CNC Turning Parts Manufacturers various certifications and accolades, solidifying its position as a reliable and reputable supplier in the industry.In addition to serving domestic clients, the company also exports its CNC turning parts to international markets, where it has gained a strong foothold due to its reputation for excellence and reliability. By leveraging its expertise and capabilities, China CNC Turning Parts Manufacturers is able to support businesses worldwide with high-quality components that are essential for various applications and industries.As global demand for precision CNC turning parts continues to rise, China CNC Turning Parts Manufacturers is poised for continued growth and success. The company's unwavering dedication to quality, innovation, and customer satisfaction has positioned it as a preferred partner for businesses seeking top-notch CNC turning solutions. With its advanced capabilities and commitment to excellence, China CNC Turning Parts Manufacturers is well-equipped to meet the evolving needs of the manufacturing industry and deliver superior results for its clients.

High-Quality Heat Resistant Rubber Gasket for Industrial Applications

Heat Resistant Rubber Gasket, an essential component for sealing and insulating applications in various industries, has become a vital product in the market. Acting as a barrier to prevent the leakage of fluids or gas, this innovative product has been revolutionizing the way industries operate. With its superior heat resistance and durability, it has significantly enhanced the performance of equipment and machinery, making it an indispensable material for various industrial processes.{Company Name}, a leading manufacturer of rubber gaskets, has been at the forefront of producing high-quality and heat-resistant gaskets for a wide range of applications. With a strong focus on innovation and product development, the company has been able to meet the ever-evolving demands of the industry and provide cutting-edge solutions to its customers. The superior performance and reliability of their products have made them a trusted name in the industry.The heat-resistant rubber gaskets manufactured by {Company Name} are engineered to withstand extreme temperatures and harsh operating conditions. Whether it is in the automotive, aerospace, energy, or manufacturing industry, these gaskets have proven to be highly reliable and efficient. With properties that allow them to maintain their integrity and sealing capabilities at high temperatures, they have become the go-to choice for applications where heat resistance is critical.One of the key features that set {Company Name}'s heat-resistant rubber gaskets apart is their exceptional durability and long service life. Designed to withstand exposure to heat, pressure, and environmental factors, these gaskets have been proven to outperform conventional sealing materials. This has resulted in reduced maintenance costs and downtime for the end-users, making them a cost-effective solution in the long run.{Company Name} takes pride in its state-of-the-art manufacturing facilities and stringent quality control measures. Utilizing advanced technologies and production processes, the company ensures that its heat-resistant rubber gaskets meet the highest industry standards and specifications. Each gasket undergoes rigorous testing to guarantee its performance and reliability, providing customers with peace of mind in their applications.In addition to their exceptional product quality, {Company Name} is renowned for its commitment to customer satisfaction and technical support. The company's team of experts works closely with customers to understand their specific requirements and provide tailored solutions to meet their needs. Whether it is customizing gaskets for unique applications or providing technical assistance, {Company Name} prides itself on delivering exceptional customer service.As the demand for heat-resistant rubber gaskets continues to grow across industries, {Company Name} remains dedicated to driving innovation and delivering cutting-edge solutions to its customers. The company's continuous investment in research and development, coupled with its commitment to excellence, positions it as a leader in the industry. With a strong focus on quality, performance, and customer satisfaction, {Company Name} is poised to meet the evolving needs of the market and maintain its reputation as a trusted supplier of heat-resistant rubber gaskets.In conclusion, the rise of heat-resistant rubber gaskets has significantly impacted various industries, providing a reliable and efficient solution for sealing and insulation applications. {Company Name}, with its expertise in manufacturing high-quality gaskets, has played a crucial role in meeting the increasing demand for these innovative products. Through its commitment to excellence, innovation, and customer satisfaction, {Company Name} has established itself as a leader in the industry and continues to set the benchmark for heat-resistant rubber gaskets.

Top Clear Plastic Molding Techniques for Your Project

Clear Plastic Molding Company, a leading provider of high-quality plastic molding solutions, has been making significant strides in the industry. With a commitment to innovation and excellence, the company has built a strong reputation for delivering top-notch products to its clients. Clear Plastic Molding Company has been in the business for over two decades and has established itself as a trusted partner for businesses in need of custom plastic molding solutions.The company specializes in clear plastic molding, offering a wide range of services including injection molding, blow molding, and thermoforming. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing them to produce complex and intricate plastic parts with precision and efficiency. Whether it's a small run of prototypes or a large-scale production, Clear Plastic Molding Company has the capabilities to meet the needs of their clients.One of the key strengths of Clear Plastic Molding Company is its dedication to quality. The company adheres to strict quality control measures at every step of the manufacturing process to ensure that the final products meet the highest standards. From raw material sourcing to final inspection, Clear Plastic Molding Company goes above and beyond to deliver products that are durable, reliable, and visually appealing.In addition to quality, Clear Plastic Molding Company also prioritizes customer satisfaction. The company has a team of experienced engineers and designers who work closely with clients to understand their specific requirements and deliver custom solutions that meet their needs. From concept and design to production and delivery, Clear Plastic Molding Company provides end-to-end support to its clients, ensuring a smooth and hassle-free experience.Furthermore, Clear Plastic Molding Company is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes recyclable materials whenever possible, reducing its carbon footprint and contributing to a more sustainable future. Clear Plastic Molding Company understands the importance of environmental conservation and strives to minimize its impact on the planet.Clear Plastic Molding Company has a diverse client base, serving a wide range of industries including automotive, medical, consumer goods, and electronics. The company's ability to adapt to the unique requirements of each industry has earned it a favorable reputation among its clients. Whether it's producing intricate medical device components or durable automotive parts, Clear Plastic Molding Company has the expertise and resources to deliver exceptional results.Looking ahead, Clear Plastic Molding Company is focused on further expanding its capabilities and enhancing its offerings. The company is continuously investing in research and development to stay at the forefront of innovation in plastic molding technology. Additionally, Clear Plastic Molding Company is exploring new opportunities for growth, including potential partnerships and collaborations that will enable it to reach new markets and serve a broader range of clients.In conclusion, Clear Plastic Molding Company is a leading provider of clear plastic molding solutions, known for its commitment to quality, customer satisfaction, and sustainability. With a focus on innovation and excellence, the company has established itself as a trusted partner for businesses in need of custom plastic molding services. As the industry continues to evolve, Clear Plastic Molding Company is well-positioned to thrive and further solidify its position as a top-tier provider of plastic molding solutions.

Top Tips for Machining Prototyping in Manufacturing

Machining Prototyping is a leading provider of precision machining and prototyping services, offering a wide range of solutions to meet the needs of various industries. With a commitment to quality, innovation, and customer satisfaction, Machining Prototyping has become a trusted partner for companies looking to bring their designs to life.The company specializes in CNC machining, 3D printing, and rapid prototyping, utilizing advanced technologies and state-of-the-art equipment to deliver high-quality parts and prototypes. Whether it's a small batch of custom parts or a complex prototype, Machining Prototyping has the expertise and capabilities to turn ideas into reality.One of the key factors that sets Machining Prototyping apart from its competitors is its dedication to continuous improvement and innovation. The company invests in research and development, staying at the forefront of industry trends and technologies to ensure that its customers receive the best possible solutions for their projects.Machining Prototyping's team of skilled engineers and technicians work closely with clients to understand their requirements and provide tailored solutions that meet their exact specifications. From the initial design phase to the final product, the company's collaborative approach ensures that all projects are completed with precision and efficiency.In addition to its machining and prototyping services, Machining Prototyping also offers design assistance and engineering support to help clients optimize their designs for manufacturability. By leveraging its extensive knowledge and expertise, the company helps customers streamline the production process and achieve cost-effective solutions without compromising on quality.With a strong focus on customer satisfaction, Machining Prototyping places great importance on communication and transparency throughout the entire project lifecycle. The company's responsive and dedicated customer support team ensures that clients are kept informed at every stage, providing peace of mind and confidence in the final outcome.Moreover, Machining Prototyping is committed to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality control measures and ethical standards, utilizing eco-friendly materials and processes whenever possible.In recent news, Machining Prototyping has expanded its capabilities with the acquisition of new cutting-edge equipment, further enhancing its ability to deliver complex and high-precision parts and prototypes. This strategic investment demonstrates the company's ongoing commitment to staying ahead of the curve and meeting the evolving needs of its customers."We are excited to announce the addition of [new equipment] to our facility, which will enable us to take on even more challenging projects and deliver unmatched quality to our clients," said [spokesperson], [title] at Machining Prototyping. "This expansion is a testament to our dedication to innovation and excellence, and we look forward to continuing to provide top-tier solutions to our valued partners."As Machining Prototyping continues to grow and evolve, the company remains steadfast in its mission to be a trusted partner for businesses seeking reliable, high-quality machining and prototyping services. With a focus on innovation, efficiency, and customer satisfaction, Machining Prototyping is well-positioned to meet the demands of today's fast-paced and competitive market.Whether it's a small startup or a large multinational corporation, Machining Prototyping stands ready to support businesses of all sizes and industries with their machining and prototyping needs. With a proven track record of success and a reputation for excellence, the company is poised to continue its upward trajectory and solidify its position as a leader in the industry.

Learn about the latest advancements in polymer moulding technology

[Company Name] Polymer Moulding is a leading provider of high-quality polymer moulding products in the industry. With a strong emphasis on innovation and customer satisfaction, [Company Name] has been serving a wide range of industries for over 20 years. As a trusted partner to its clients, [Company Name] Polymer Moulding has established a strong reputation for delivering top-notch products and exceptional service.The company specializes in the manufacturing of polymer moulded products for various applications, including automotive, construction, electronics, and medical devices. With state-of-the-art manufacturing facilities and a highly skilled team of professionals, [Company Name] Polymer Moulding has the capabilities to produce custom moulded products that meet the specific requirements of its clients.In addition to its manufacturing capabilities, [Company Name] Polymer Moulding is committed to sustainability and environmental responsibility. The company utilizes advanced and eco-friendly processes to minimize its environmental impact and ensure that its products are safe for the environment.Recently, [Company Name] Polymer Moulding has announced a new initiative to expand its product line and enhance its production capabilities. The company has invested in new machinery and technology to increase its capacity and improve the quality of its products. This investment reflects [Company Name]'s commitment to staying at the forefront of the industry and meeting the evolving needs of its customers.One of the key areas of focus for [Company Name] Polymer Moulding is the development of advanced materials and processes. By investing in research and development, the company aims to create innovative solutions that offer superior performance and durability. This commitment to innovation has helped [Company Name] Polymer Moulding maintain its position as a trusted supplier to some of the leading companies in the industry.Furthermore, [Company Name] Polymer Moulding is dedicated to fostering strong partnerships with its customers. The company works closely with its clients to understand their unique requirements and provide tailored solutions that meet their exact specifications. By maintaining open communication and delivering on its promises, [Company Name] Polymer Moulding has built lasting relationships with its customers, who rely on the company for their polymer moulding needs.In addition to its focus on customer satisfaction, [Company Name] Polymer Moulding is also committed to providing a safe and supportive work environment for its employees. The company values its team members and invests in their professional development, training, and well-being.As [Company Name] Polymer Moulding continues to grow and expand its capabilities, the company remains dedicated to upholding its core values of integrity, quality, and innovation. By staying true to these values, [Company Name] Polymer Moulding has established itself as a leader in the polymer moulding industry, and is well-positioned to meet the evolving needs of its customers in the years to come.

Injection Molding: A Guide to IML Technology

Iml Injection Molding is a leading manufacturing process that has revolutionized the production of plastic parts. This innovative technology has allowed companies to produce high-quality, durable, and intricate plastic components with unparalleled precision and efficiency. With the use of advanced machinery, high-grade materials, and sophisticated software, Iml Injection Molding has become the preferred choice for many industries, including automotive, electronics, consumer goods, and medical devices. The process involves injecting molten plastic into a mold cavity, where it is shaped and cooled to form a finished product. The In-Mold Labeling (IML) technology further enhances the product by incorporating the label or decoration directly into the mold, resulting in a seamless and durable finish.The company {} has been at the forefront of this technological advancement, offering a wide range of Iml Injection Molding solutions to meet the diverse needs of its clients. With state-of-the-art facilities, a highly skilled workforce, and a commitment to excellence, {} has established itself as a reliable and innovative partner for businesses seeking top-notch plastic manufacturing services.{} specializes in custom mold design and fabrication, precision injection molding, and in-mold labeling for various industries. From automotive interior parts and electronic housings to food packaging and medical devices, {} has the expertise and capabilities to deliver complex and high-quality plastic components that meet the highest industry standards.One of the key advantages of Iml Injection Molding is its ability to produce parts with intricate designs and complex geometries. This is made possible through the use of specialized molds and advanced machinery that can achieve tight tolerances and superior surface finishes. As a result, products manufactured using Iml Injection Molding are not only visually appealing but also functionally superior, making them ideal for a wide range of applications.In addition to its technical capabilities, {} places a strong emphasis on sustainability and environmental responsibility. The company is committed to using recyclable materials, reducing waste, and optimizing energy consumption in its manufacturing processes. By adopting eco-friendly practices, {} not only contributes to a healthier planet but also helps its clients meet their sustainability goals.Moreover, {} is dedicated to continuous improvement and innovation. The company invests in research and development to stay ahead of the latest industry trends and technology advancements. By embracing new materials, processes, and design techniques, {} ensures that its clients receive cutting-edge solutions that give them a competitive edge in their respective markets.As a customer-centric company, {} prides itself on its ability to provide tailored solutions that meet the unique requirements of each client. By collaborating closely with its customers, {} gains a deep understanding of their needs and preferences, allowing the company to deliver personalized and cost-effective Iml Injection Molding solutions that exceed expectations.With a strong track record of delivering exceptional results, {} has earned the trust and loyalty of its clients, who rely on the company for their most demanding plastic manufacturing projects. By consistently delivering top-quality products, on-time delivery, and responsive customer service, {} has built a reputation as a partner that businesses can depend on for their Iml Injection Molding needs.In conclusion, Iml Injection Molding is a game-changer in the world of plastic manufacturing, and {} is at the forefront of this technological revolution. With its advanced capabilities, commitment to sustainability, and customer-centric approach, {} is well-positioned to continue leading the way in delivering high-quality and innovative Iml Injection Molding solutions. Businesses seeking a reliable and forward-thinking manufacturing partner need look no further than {}.

Top Tips for Successful Injection Molding

Injection molding is a highly versatile method used in the manufacturing industry to produce a wide range of products and components. This process involves melting a thermoplastic material and injecting it into a mold cavity, where it is then cooled and solidified to form the desired shape. One company at the forefront of injection molding technology is {}. With their state-of-the-art facilities and advanced machinery, they have been able to offer innovative solutions to their clients across various industries. {} has built a strong reputation for delivering high-quality products and components using injection molding. They have a team of experienced engineers and technicians who work closely with clients to understand their specific requirements and provide customized solutions. From design and prototyping to production and assembly, {} offers a comprehensive range of services to meet the needs of their clients. The company is committed to staying ahead of the curve when it comes to injection molding technology. They continuously invest in the latest machinery and equipment to ensure that they are able to deliver precise and efficient manufacturing solutions. This commitment to innovation has enabled {} to stay competitive in the market and maintain their position as a leading provider of injection molded products.In addition to their technical capabilities, {} also places a strong emphasis on quality control and process optimization. They have implemented strict quality management systems to ensure that each product that comes out of their facility meets the highest standards. This dedication to quality has earned them the trust and confidence of their clients, who rely on {} to deliver reliable and durable products.{} serves a diverse range of industries, including automotive, consumer electronics, medical, and more. Their ability to cater to the unique needs of each industry and provide tailored solutions sets them apart from their competitors. Whether it's manufacturing precision components for the automotive sector or producing medical devices with strict regulatory requirements, {} has the expertise and resources to deliver on their clients' expectations.As a responsible corporate citizen, {} is also committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes and strive to minimize their environmental footprint. By using recyclable materials and optimizing their energy consumption, {} is dedicated to reducing their impact on the environment while still delivering exceptional products.Looking towards the future, {} is poised to continue leading the way in injection molding technology. They are continuously exploring new materials, processes, and techniques to improve their capabilities and expand their offerings. By staying at the forefront of technological advancements, {} is well-positioned to meet the evolving needs of their clients and remain a trusted partner in the manufacturing industry.In conclusion, injection molding is a crucial process in the manufacturing industry, and {} has established itself as a key player in this field. With their commitment to innovation, quality, and sustainability, they have earned a strong reputation and a loyal client base. As they continue to invest in their capabilities and adapt to the changing industry landscape, {} is well-prepared to maintain their leadership position and drive the future of injection molding technology.

Benefits of Prototype Plastic Molding for your Business

Prototype Plastic Molding, a leading provider of custom plastic injection molding solutions, has recently expanded their services to better serve the growing demand for high-quality plastic parts in various industries. With over 20 years of experience in the industry, Prototype Plastic Molding has become a trusted partner for companies looking for reliable and cost-effective plastic molding solutions.The company is known for its state-of-the-art facilities, highly skilled team of engineers and technicians, and commitment to delivering top-notch products to their clients. They offer a wide range of services including product design and development, mold making, injection molding, assembly, and packaging. Their expertise in the field has allowed them to work with clients in industries such as automotive, medical, consumer goods, and more.One of the key factors that set Prototype Plastic Molding apart from their competitors is their dedication to using the latest technology and equipment in their manufacturing processes. This allows them to produce parts with high precision, consistency, and efficiency, while also reducing lead times and overall costs for their clients.In response to the increasing demand for sustainable manufacturing practices, Prototype Plastic Molding has also made significant investments in environmentally friendly initiatives. They have implemented processes and materials to reduce waste, minimize energy consumption, and decrease their carbon footprint. This commitment to sustainability not only benefits the environment but also positions them as a forward-thinking and socially responsible partner for their clients.As part of their expansion efforts, Prototype Plastic Molding has recently added new injection molding machines to their production line. These machines are equipped with the latest technology to improve efficiency and capacity, allowing the company to take on larger and more complex projects. Additionally, they have expanded their workforce to accommodate the growing demand for their services, hiring new talent with expertise in various aspects of plastic molding.The company's dedication to continuous improvement and innovation has earned them a solid reputation in the industry. They are committed to staying ahead of the curve and offering cutting-edge solutions to their clients. This dedication has led to long-standing partnerships with many of their clients, who rely on Prototype Plastic Molding for their expertise and reliability.In addition to their expansion efforts, Prototype Plastic Molding also remains focused on providing exceptional customer service. They understand the importance of clear communication, attention to detail, and on-time delivery for their clients. Their team works closely with each client to understand their specific needs and develop customized solutions that meet their requirements.Looking ahead, Prototype Plastic Molding is poised for continued growth and success in the industry. They are committed to staying at the forefront of plastic molding technology, expanding their capabilities, and providing even greater value to their clients. With their dedication to quality, innovation, and customer satisfaction, Prototype Plastic Molding is well-positioned to remain a leader in the custom plastic injection molding industry for years to come.