- Home

- Double Shot Injection Molding

Double Shot Injection Molding Manufacturer and Supplier in China

Introducing the latest innovation in plastic molding technology - double shot injection molding. Shenzhen RCT MFG Co., Ltd. is proud to be at the forefront of this cutting-edge manufacturing process, offering cheap yet high-quality solutions for your plastic product needs.

With our state-of-the-art equipment and experienced team, we are able to provide double shot injection molding services that allow for the creation of complex, two-color or two-material parts in a single operation. This not only streamlines the manufacturing process but also produces more durable and aesthetically pleasing products.

As a trusted manufacturer, supplier, and factory, Shenzhen RCT MFG Co., Ltd. is committed to delivering exceptional results and cost-effective solutions to our clients. Whether you require custom-designed components or mass-produced parts, our double shot injection molding capabilities ensure that your project is completed with precision and efficiency. Contact us today to discuss how we can bring your plastic product ideas to life.

Shenzhen RCT MFG CO., LTD

Company News

Related News

High precision injection molds industrial machine injection mould

Introducing our High Precision Injection Molds Industrial Machine Injection Mould. As a factory, we provide top-quality molds for your industrial needs.

Automotive Plastic Parts injection molding

Plastimold is a leading manufacturer of Automotive Plastic Parts with injection molding technology. We are a trusted factory for high-quality automotive components.

Precision biodegradable PLA Bioplastic Injection Molding

Get high-quality precision biodegradable PLA bioplastic injection molding at our factory. We offer eco-friendly solutions for your manufacturing needs.

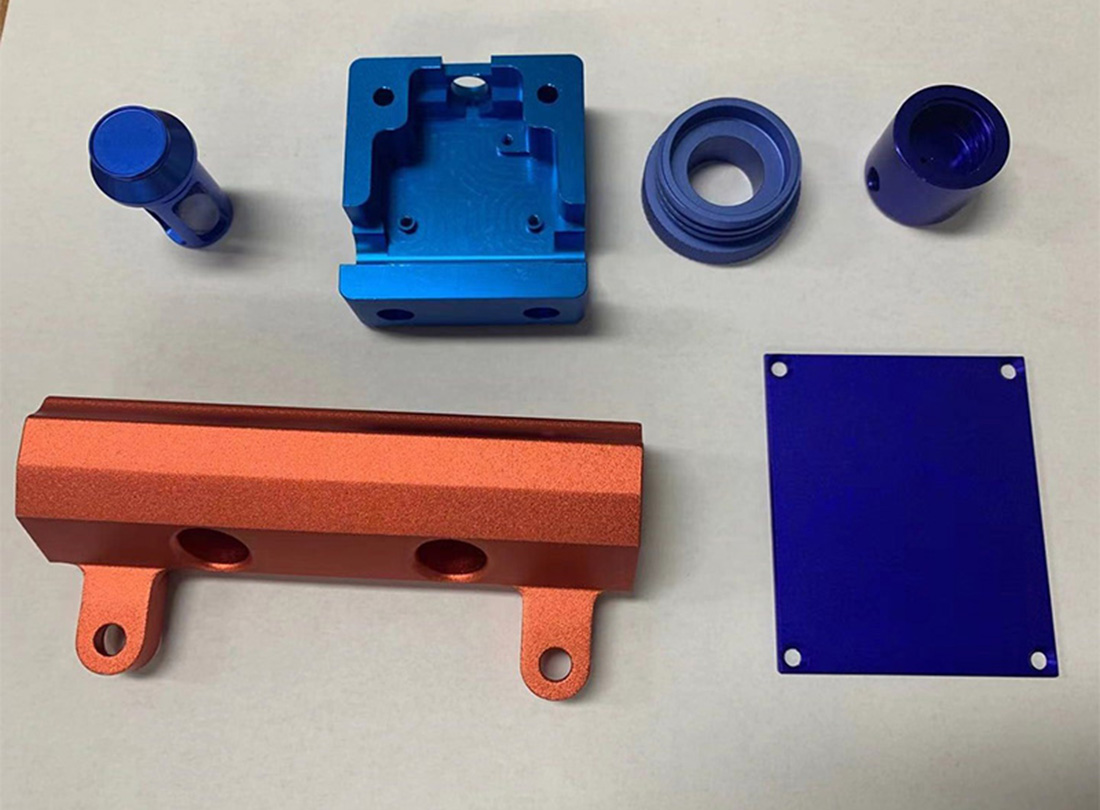

Precision anodized 7075 Aluminium Machined Wheels for Automative

Upgrade your vehicle with our precision anodized 7075 aluminium machined wheels for automotive. Shop directly from our factory for high-quality and durable wheels.

CNC Turning and Milling Delrin/POM parts

Precise Delrin parts with CNC Turning and Milling. High quality POM components manufactured in our factory. Custom orders welcome. Contact us today." #CNC #Delrin #POM #manufacturing

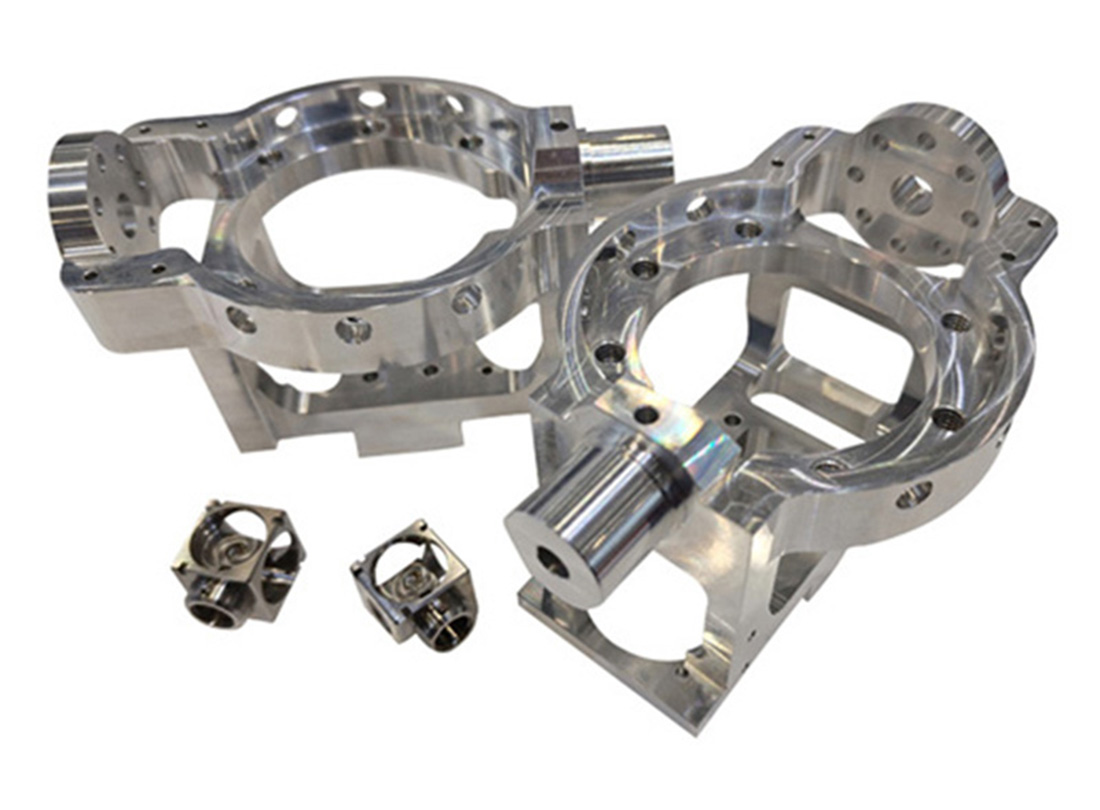

CNC Machining of stainless steel housigg for the Gas Compression Equipment Industry

Stainless Steel Housing for Gas Compression Equipment - CNC Machining. We are a factory specializing in high-quality stainless steel housings for the gas compression industry.

Aluminum 6061 CNC machining Precision Parts for Electronics

Aluminum 6061 CNC machining Precision Parts for Electronics | We are a factory specializing in high-quality custom aluminum parts for electronic devices. Contact us today!

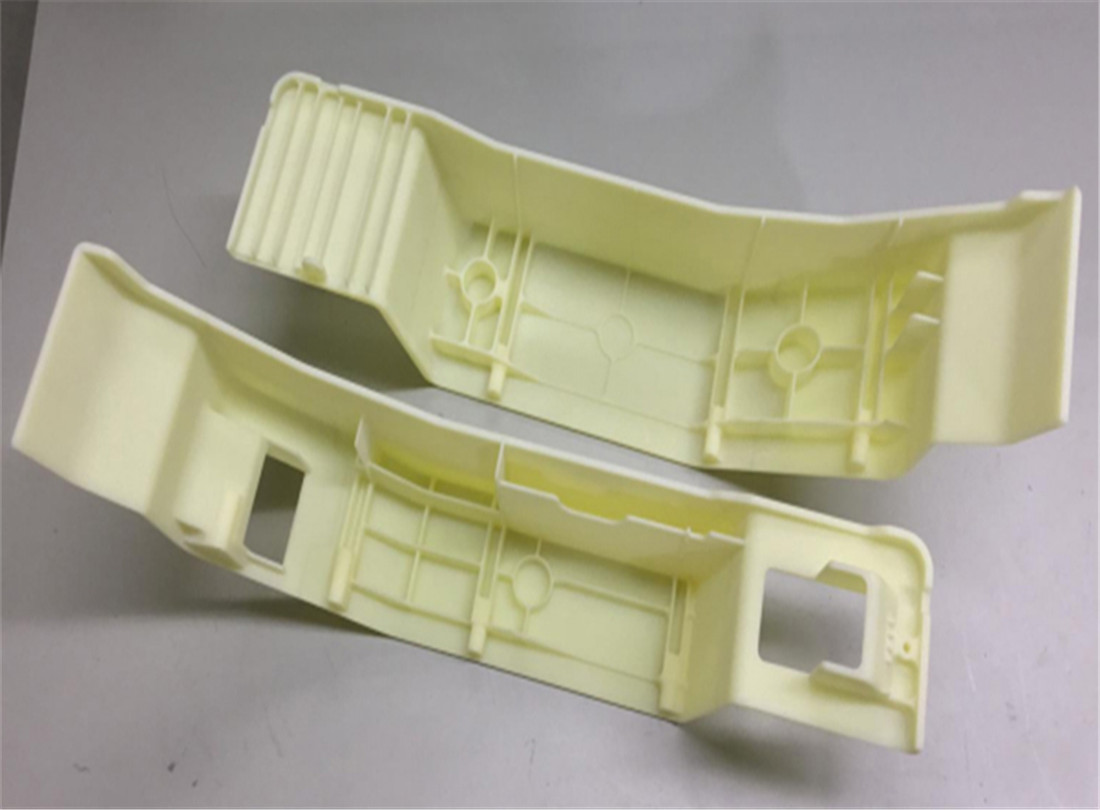

Low Volume Production Automative spare parts Urethane Casting

Introducing our new line of Low Volume Production Automative spare parts Urethane Casting. As a factory, we deliver high-quality and durable parts.

Red anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts

Red Anodized Aluminum 7075 Milling/Turning/Drilling Machine Parts - High-quality precision parts manufactured in our factory. Order now for reliable performance.

Custom Aluminium enclosure sheet metal fabrication

Custom Aluminium Enclosure Sheet Metal Fabrication - We are a factory specializing in precision sheet metal fabrication for custom aluminium enclosures.

New RCT CNC Machining ABS plastic parts prototype for product development

Introducing the New RCT CNC Machining ABS plastic parts prototype for product development. Our factory specializes in precision manufacturing.

Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

Get high-quality custom A380 ADC12 aluminum die cast parts from our Shenzhen factory. We specialize in die casting for various industries.

CNC Milling of High Precision Aluminum Machined Parts for the Process Fluid Circulation Industry

Get high precision aluminum machined parts for the process fluid circulation industry with our CNC milling services. Factory-direct quality and reliability.

Customized High Precision CNC Machining Parts for Aquatic Products Testing Equipmen

Precision CNC Machining Parts for Aquatic Products Testing Equipmen by a reliable factory. Customized and high-quality parts for accurate testing."

Silicone Parts Moulding Rubber Black Irregular Shape Custom Silicone Parts

Custom Silicone Parts - Irregular Shape Black Silicone Moulding Rubber for various applications. Factory direct, durable and high-quality silicone parts.

- Double Shot Injection Molding Manufacturer and Supplier in China

- Reviews

- Related Videos

Introducing our latest innovation in plastic molding technology - Double Shot Injection Molding. This cutting-edge technique allows us to produce complex, multi-material parts with precision and efficiency, revolutionizing the way products are designed and manufactured. With Double Shot Injection Molding, two different materials can be injected into a mold in a single process, creating seamless, high-quality parts with unique aesthetics and enhanced functionality. This method opens up a world of possibilities for creating products with varying textures, colors, and properties, all in one seamless production cycle. Our advanced Double Shot Injection Molding technology enables us to meet the demands of diverse industries, from automotive and electronics to consumer goods and medical devices. By combining multiple materials in a single part, we can achieve superior performance and durability, while reducing the need for assembly and additional processes. Not only does Double Shot Injection Molding offer cost-effective solutions, but it also allows for greater design flexibility and faster time-to-market. This means our customers can bring their innovative ideas to life more efficiently and competitively. Experience the future of plastic molding with our Double Shot Injection Molding technology and unleash the full potential of your product designs. Contact us today to learn how our expertise in multi-material molding can elevate your next project.

I recently purchased a product that was made using double shot injection molding and I am thoroughly impressed with the results. The precision and accuracy of the dual injection process have resulted in a high-quality and durable product. The two-step molding process has allowed for intricate designs and patterns to be seamlessly integrated into the product, giving it a sleek and professional finish. The material also feels strong and long-lasting, ensuring that the product will hold up to daily wear and tear. Overall, I am extremely satisfied with the quality and craftsmanship of this double shot injection molded product.

I recently purchased a product that was manufactured using the double shot injection molding process and I couldn't be more impressed. The detail and precision of the product are truly remarkable, and the dual material design adds a level of versatility and functionality that sets it apart from other products. The durability and strength of the double shot injection molding process make for a high-quality end product that I know will last for years to come. I highly recommend looking for products that utilize double shot injection molding if you want something that's built to last and offers a unique design.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours