Durable and High-Quality Silicone Parts for Various Applications

By:Admin

Silicone Parts Company specializes in the production of a wide range of silicone products, including gaskets, seals, O-rings, and custom-molded parts. Their silicone parts are known for their durability, flexibility, and resistance to extreme temperatures, making them ideal for a variety of industries, including automotive, medical, food and beverage, and aerospace. The company's state-of-the-art manufacturing facilities and cutting-edge technology allow them to produce high-quality silicone parts that meet the most stringent industry standards.

The latest range of silicone parts from Silicone Parts Company includes innovative designs and advanced materials that offer improved performance and longevity. The company has invested heavily in research and development to ensure that their products are at the forefront of technological advancements in the silicone industry. With a team of experienced engineers and technicians, Silicone Parts Company continues to push the boundaries of what is possible with silicone, driving innovation and setting new standards for excellence.

"We are excited to introduce our latest range of silicone parts to the market," said the CEO of Silicone Parts Company. "Our team has worked tirelessly to develop these new products, and we are confident that they will exceed our customers' expectations in terms of quality and performance. We are committed to providing the best silicone parts on the market, and this new range is a testament to that commitment."

Silicone Parts Company prides itself on its ability to provide custom solutions to meet the unique needs of each customer. Whether it's a specific size, shape, or material requirement, the company's dedicated team works closely with clients to create customized silicone parts that precisely meet their specifications. This commitment to personalized service has earned Silicone Parts Company a reputation for being a trusted and reliable partner to businesses across a wide range of industries.

In addition to their dedication to producing high-quality silicone parts, Silicone Parts Company is also committed to sustainability and environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials, ensuring that their products have minimal impact on the environment. By prioritizing sustainability, Silicone Parts Company sets itself apart as a socially responsible and forward-thinking organization.

Silicone Parts Company serves a global customer base, with distribution channels and sales offices in key markets around the world. Their commitment to excellence and customer satisfaction has earned them a loyal clientele and a strong reputation for reliability and dependability. As they continue to expand their product range and reach new markets, Silicone Parts Company remains focused on delivering superior silicone parts that meet the evolving needs of their customers.

With the launch of their latest range of innovative silicone parts, Silicone Parts Company reaffirms its position as a leader in the industry. Their unwavering dedication to quality, precision, and customer satisfaction sets them apart as a trusted partner for businesses seeking high-quality silicone parts. As they continue to push the boundaries of innovation and excellence, Silicone Parts Company looks forward to setting new standards for the silicone industry and providing cutting-edge solutions to their valued customers.

Company News & Blog

High Precision CNC Mill for Superior Machining

High Precision CNC Mill Revolutionizes Manufacturing IndustryWith the continuous advancement in technology, the manufacturing industry is witnessing a significant transformation. The introduction of high precision CNC mills has taken manufacturing to a new level, enabling companies to produce complex and intricate components with unparalleled precision and accuracy. One such company at the forefront of this technological revolution is {}, a leading manufacturer of advanced CNC machines. With a strong focus on innovation and quality, the company has been driving the industry forward with its cutting-edge technology and state-of-the-art solutions.The high precision CNC mill developed by {} has set a new benchmark in the industry, offering unmatched levels of precision and efficiency. This advanced machine is equipped with the latest control systems and cutting-edge software, allowing for seamless integration of complex designs and precise machining operations. The result is a finished product that meets the highest standards of quality and accuracy.One of the key features of the high precision CNC mill is its ability to produce components with tight tolerances and intricate geometries. This has opened up new possibilities for companies across a wide range of industries, including aerospace, automotive, medical, and electronics. The ability to produce complex parts with high precision has enabled manufacturers to push the boundaries of what is possible, leading to innovation and advancements in various sectors.In addition to its precision capabilities, the CNC mill also offers high levels of productivity and efficiency. The advanced automation features and powerful cutting tools allow for rapid production of components, reducing lead times and increasing overall throughput. This has led to significant improvements in manufacturing processes, resulting in higher productivity and cost savings for companies utilizing this technology.Another important aspect of the high precision CNC mill is its versatility. It is capable of machining a wide range of materials, including metals, plastics, and composites, making it suitable for a variety of applications. This flexibility has made the CNC mill a valuable asset for companies looking to expand their capabilities and take on a diverse range of projects.Furthermore, the CNC mill has been designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up, program, and monitor machining operations. This has reduced the learning curve for operators, allowing them to quickly adapt to the new technology and maximize its potential.Moreover, the high precision CNC mill is equipped with advanced safety features to ensure a secure working environment for operators. With built-in sensors and safety protocols, the machine is able to detect and respond to potential hazards, minimizing the risk of accidents and injuries in the workplace.{} has also been proactive in providing comprehensive training and support for its customers, ensuring that they have the knowledge and resources to fully utilize the capabilities of the high precision CNC mill. This commitment to customer satisfaction has helped the company build a strong reputation in the industry, with a track record of delivering reliable and high-performance machines.Overall, the introduction of high precision CNC mills has been a game-changer for the manufacturing industry, offering a level of precision, efficiency, and versatility that was previously unattainable. As technology continues to evolve, the potential for further advancements in CNC machining is limitless, and companies like {} are leading the way in shaping the future of manufacturing.

Advancements in Plastic Injection Molding Technology

The Plastic Injection Company Empowering Manufacturers with Advanced Mold TechnologyWith the global demand for high-quality plastic products on the rise, manufacturers are constantly seeking innovative solutions to enhance their production processes. The Plastic Injection Company, a leading provider of advanced mold technology, is paving the way for manufacturers to achieve greater precision, efficiency, and cost-effectiveness in their plastic injection operations.The Plastic Injection Company is renowned for its expertise in developing top-notch mold plastic injection systems that are tailored to meet the specific needs of manufacturers across various industries. Their cutting-edge technology and commitment to quality have made them a preferred partner for businesses looking to optimize their plastic injection processes.As a pioneer in the field, The Plastic Injection Company has established a solid reputation for delivering exceptional mold plastic injection solutions that enable manufacturers to achieve superior results. Their team of skilled engineers and technicians are dedicated to designing and manufacturing high-performance mold systems that meet the most stringent industry standards.The company’s state-of-the-art facilities are equipped with the latest equipment and technology, allowing them to produce precision molds that are unrivaled in terms of quality and durability. Whether it’s a complex mold design or a high-volume production run, The Plastic Injection Company has the expertise and resources to deliver outstanding results.Moreover, The Plastic Injection Company places a strong emphasis on customer satisfaction, striving to provide personalized service and support to every client. They work closely with manufacturers to understand their unique requirements and develop customized mold plastic injection solutions that are tailored to their specific needs.In addition to their technical expertise, The Plastic Injection Company is committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes, such as using recyclable materials and reducing waste, to minimize their environmental impact and contribute to a greener future.Furthermore, The Plastic Injection Company has a strong commitment to continuous innovation and research, staying ahead of industry trends and technological advancements. Their R&D team is constantly exploring new materials, processes, and techniques to further enhance the performance and efficiency of their mold plastic injection systems.The Plastic Injection Company’s dedication to excellence has earned them the trust of manufacturers worldwide, who rely on their expertise to enhance their production capabilities and gain a competitive edge in the market. Their relentless pursuit of perfection and unwavering commitment to quality have made them a go-to partner for businesses seeking reliable and efficient mold plastic injection solutions.With a proven track record of success and a relentless drive for innovation, The Plastic Injection Company is poised to continue leading the way in the mold plastic injection industry. Their steadfast commitment to delivering outstanding results and exceptional customer service sets them apart as a trusted and reliable partner for manufacturers seeking to elevate their plastic injection operations.In conclusion, The Plastic Injection Company’s unwavering dedication to excellence, innovation, and customer satisfaction has positioned them as a formidable force in the mold plastic injection industry. With their advanced technology, personalized service, and commitment to sustainability, they empower manufacturers to achieve greater efficiency, precision, and success in their plastic injection processes. As the demand for high-quality plastic products continues to grow, The Plastic Injection Company remains at the forefront, driving industry advancements and paving the way for a brighter future.

High-Quality Heat Resistant Rubber Gasket for Industrial Applications

Heat Resistant Rubber Gasket, an essential component for sealing and insulating applications in various industries, has become a vital product in the market. Acting as a barrier to prevent the leakage of fluids or gas, this innovative product has been revolutionizing the way industries operate. With its superior heat resistance and durability, it has significantly enhanced the performance of equipment and machinery, making it an indispensable material for various industrial processes.{Company Name}, a leading manufacturer of rubber gaskets, has been at the forefront of producing high-quality and heat-resistant gaskets for a wide range of applications. With a strong focus on innovation and product development, the company has been able to meet the ever-evolving demands of the industry and provide cutting-edge solutions to its customers. The superior performance and reliability of their products have made them a trusted name in the industry.The heat-resistant rubber gaskets manufactured by {Company Name} are engineered to withstand extreme temperatures and harsh operating conditions. Whether it is in the automotive, aerospace, energy, or manufacturing industry, these gaskets have proven to be highly reliable and efficient. With properties that allow them to maintain their integrity and sealing capabilities at high temperatures, they have become the go-to choice for applications where heat resistance is critical.One of the key features that set {Company Name}'s heat-resistant rubber gaskets apart is their exceptional durability and long service life. Designed to withstand exposure to heat, pressure, and environmental factors, these gaskets have been proven to outperform conventional sealing materials. This has resulted in reduced maintenance costs and downtime for the end-users, making them a cost-effective solution in the long run.{Company Name} takes pride in its state-of-the-art manufacturing facilities and stringent quality control measures. Utilizing advanced technologies and production processes, the company ensures that its heat-resistant rubber gaskets meet the highest industry standards and specifications. Each gasket undergoes rigorous testing to guarantee its performance and reliability, providing customers with peace of mind in their applications.In addition to their exceptional product quality, {Company Name} is renowned for its commitment to customer satisfaction and technical support. The company's team of experts works closely with customers to understand their specific requirements and provide tailored solutions to meet their needs. Whether it is customizing gaskets for unique applications or providing technical assistance, {Company Name} prides itself on delivering exceptional customer service.As the demand for heat-resistant rubber gaskets continues to grow across industries, {Company Name} remains dedicated to driving innovation and delivering cutting-edge solutions to its customers. The company's continuous investment in research and development, coupled with its commitment to excellence, positions it as a leader in the industry. With a strong focus on quality, performance, and customer satisfaction, {Company Name} is poised to meet the evolving needs of the market and maintain its reputation as a trusted supplier of heat-resistant rubber gaskets.In conclusion, the rise of heat-resistant rubber gaskets has significantly impacted various industries, providing a reliable and efficient solution for sealing and insulation applications. {Company Name}, with its expertise in manufacturing high-quality gaskets, has played a crucial role in meeting the increasing demand for these innovative products. Through its commitment to excellence, innovation, and customer satisfaction, {Company Name} has established itself as a leader in the industry and continues to set the benchmark for heat-resistant rubber gaskets.

Ultimate Guide to Multi Component Injection Molding Process

Multi Component Injection Molding: Revolutionizing Manufacturing ProcessInjection molding has long been a key manufacturing process, but recent advancements in technology and materials have made it even more versatile and efficient. One such development is Multi Component Injection Molding, a process that has been gaining traction in the industry due to its ability to create complex and innovative products.Multi Component Injection Molding, also known as multi-shot molding, is a process that allows different materials or colors to be injected into a mold in a single operation. This enables manufacturers to create products with multiple layers, colors, or materials, all in one seamless process. The result is a finished product with enhanced functionality, aesthetics, and performance.One company at the forefront of this technology is {}. With over 20 years of experience in the plastic injection molding industry, {} has become a leader in the development and implementation of Multi Component Injection Molding processes. By investing in cutting-edge machinery and employing a team of skilled engineers and technicians, {} has been able to offer a wide range of multi-shot molding solutions to meet the diverse needs of their customers.{}'s state-of-the-art facility is equipped with the latest multi-component injection molding machines, which are capable of producing complex and high-precision parts with unmatched efficiency and accuracy. The company's commitment to quality and innovation has made them a preferred partner for many leading manufacturers across various industries.The benefits of Multi Component Injection Molding are numerous. By consolidating multiple manufacturing steps into a single operation, it reduces production time and costs, while also minimizing material waste. This results in a more sustainable and cost-effective manufacturing process, making it an attractive option for companies looking to improve their bottom line.Additionally, multi-shot molding allows for the integration of different materials with varying properties, such as hardness, flexibility, or transparency, into a single product. This opens up a world of design possibilities, enabling the creation of products that are not only visually appealing but also highly functional and durable. From automotive components to consumer electronics and medical devices, multi-component injection molding has the potential to transform the way products are designed and manufactured across industries.The automotive industry, in particular, has embraced multi-shot molding for the production of interior and exterior components, such as dashboard panels, door handles, and trim pieces. By using different materials and colors in a single mold, manufacturers can achieve a seamless and visually striking finish, all while reducing assembly and labor costs.In the consumer electronics sector, multi-component injection molding has enabled the creation of more compact and lightweight devices with improved functionality and aesthetics. From mobile phone casings to wearable technology, the ability to combine different materials and colors in one manufacturing process has given designers greater freedom to innovate and push the boundaries of product design.The medical industry has also seen significant advancements thanks to multi-shot molding. By integrating rigid and flexible materials in medical devices and equipment, manufacturers can create products that are not only comfortable for the patient but also meet the stringent requirements for safety and performance.As the demand for more innovative and complex products continues to grow, Multi Component Injection Molding is poised to play a crucial role in shaping the future of manufacturing. With its ability to streamline production processes, reduce waste, and enable advanced product designs, multi-shot molding is set to revolutionize the way products are made across industries.Companies like {} are at the forefront of this revolution, leveraging their expertise and technology to deliver cutting-edge multi-component injection molding solutions to their clients. With a commitment to quality, innovation, and customer satisfaction, {} is well-positioned to lead the way in shaping the future of manufacturing through multi-shot molding.

Innovative Laser Prototyping: A Game-Changer in Product Development

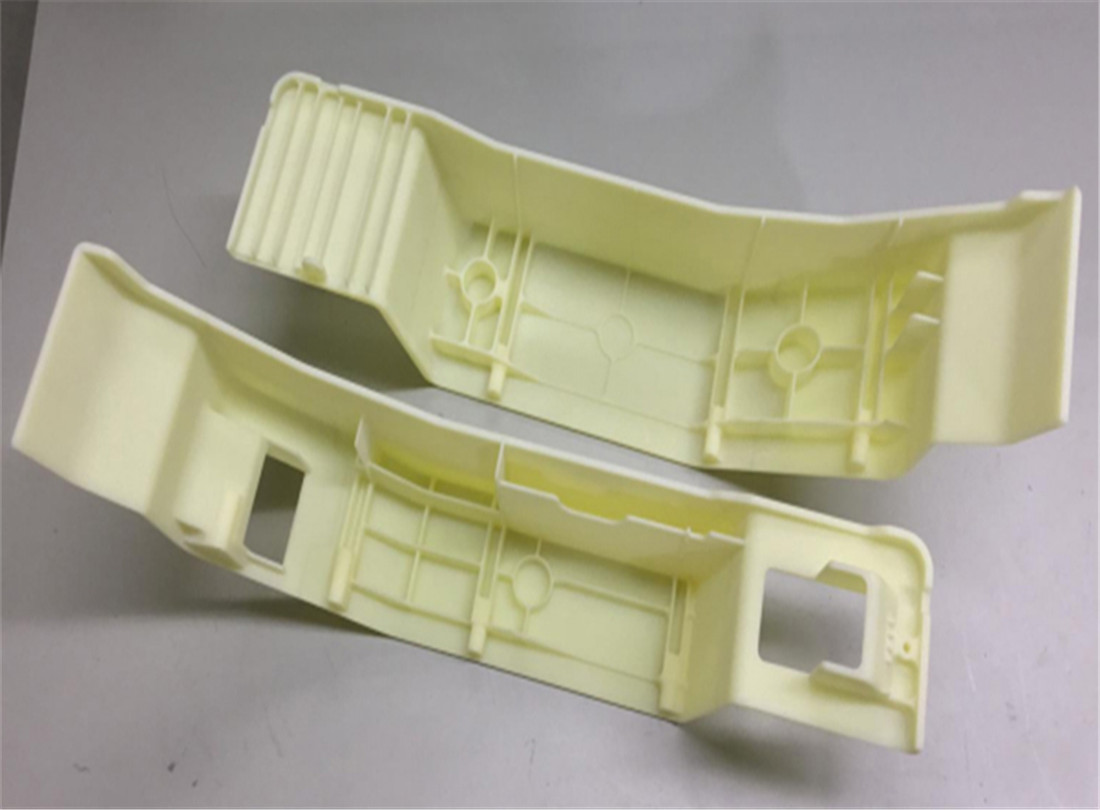

Laser Prototyping Technology Revolutionizes Manufacturing ProcessIn today's fast-paced manufacturing industry, companies are constantly striving to find innovative ways to improve their production processes and create new, cutting-edge products. One technology that is revolutionizing the manufacturing process is Laser Prototyping. This groundbreaking technology has the ability to create highly detailed and intricate prototypes with speed and precision, making it a game-changer for companies looking to stay ahead of the competition.Laser Prototyping, also known as laser 3D printing, uses a high-powered laser to selectively sinter or melt layers of powdered material, typically metal, plastic, or ceramic, to create an object. This process allows for the production of complex and intricate designs that would be difficult, if not impossible, to achieve using traditional manufacturing methods. With the ability to create prototypes with such precision, companies can quickly iterate and refine their designs, ultimately speeding up the product development process.One company at the forefront of this technology is [Company Name]. [Company Name] is a leading provider of advanced manufacturing solutions and is recognized for its expertise in laser prototyping. With state-of-the-art equipment and a team of experienced engineers, [Company Name] is able to offer its clients a wide range of prototyping services, from rapid prototyping to low-volume production runs.The use of Laser Prototyping technology has numerous benefits for manufacturers. One of the key advantages is the ability to produce prototypes rapidly. Traditional prototyping methods can be time-consuming and costly, with tooling and molds often taking weeks or even months to create. Laser Prototyping, on the other hand, allows for the creation of prototypes in a matter of hours, drastically reducing lead times and accelerating the product development cycle.Furthermore, Laser Prototyping technology offers unparalleled design freedom. With the ability to create intricate and complex geometries, designers are no longer limited by the constraints of traditional manufacturing processes. This opens up a world of possibilities for creating innovative and unique products that were previously unattainable.In addition to the speed and design flexibility, Laser Prototyping also offers cost savings for manufacturers. With the ability to create prototypes directly from digital designs, the need for expensive tooling and molds is eliminated. This not only reduces upfront costs but also allows for on-the-fly design changes without incurring additional expenses.[Company Name] has been at the forefront of advocating for the adoption of Laser Prototyping technology in the manufacturing industry. With their extensive experience and expertise in this field, [Company Name] has been able to help numerous companies leverage the benefits of Laser Prototyping to streamline their product development process and bring innovative ideas to market.To showcase the capabilities of Laser Prototyping, [Company Name] has recently launched a new line of services specifically tailored for companies looking to take advantage of this game-changing technology. Their comprehensive prototyping services cover the entire spectrum of Laser Prototyping, including design consultation, rapid prototyping, and low-volume production runs. Whether companies are looking to create a functional prototype for testing or produce a small batch of custom-designed parts, [Company Name] has the expertise and technology to bring their vision to life.As the manufacturing industry continues to evolve, it is clear that Laser Prototyping will play a pivotal role in shaping the future of product development. With the ability to create highly intricate and complex designs with speed and precision, Laser Prototyping is revolutionizing the way companies bring their ideas to life. With companies like [Company Name] leading the way, it is only a matter of time before Laser Prototyping becomes the new standard in the manufacturing industry.

Understanding the Importance of Precision in CNC Machining

CNC Precision, a leading precision machining company, has recently announced its expansion plans to meet the growing demand for its services in the manufacturing industry. The company, which specializes in providing high-quality CNC machining, has built a reputation for delivering precision parts and components to a wide range of industries, including aerospace, automotive, medical, and electronics.With the increasing demand for precision-machined parts and components, CNC Precision has recognized the need to expand its operations in order to better serve its customers. The company has invested in state-of-the-art equipment and technology to increase its production capacity and capabilities, allowing it to take on larger and more complex projects. This expansion will enable CNC Precision to meet the evolving needs of its customers and maintain its position as a market leader in the precision machining industry."We are excited to announce our expansion plans as we strive to meet the growing demand for our precision machining services," said the CEO of CNC Precision. "Our investment in new technology and equipment will enable us to provide our customers with even higher quality products and faster turnaround times. This expansion is a testament to our commitment to being a reliable and innovative partner for our customers."In addition to increasing its production capacity, CNC Precision is also focused on expanding its workforce to accommodate the growing demand for its services. The company is actively recruiting skilled machinists, engineers, and support staff to join its team and contribute to its continued success. By investing in its team and facilities, CNC Precision aims to continue providing exceptional service and value to its customers.As part of its expansion plans, CNC Precision is also exploring opportunities to broaden its customer base and expand its presence in new markets. The company is actively seeking partnerships and collaborations with other organizations in the manufacturing industry to further enhance its capabilities and reach. By forging strategic alliances, CNC Precision aims to leverage its expertise and resources to deliver added value to its customers and accelerate its growth.CNC Precision's commitment to innovation, quality, and customer satisfaction has been the driving force behind its success. The company's dedication to investing in advanced technology, expanding its capabilities, and attracting top talent has positioned it as a trusted partner for a wide range of industries. As CNC Precision continues to expand and evolve, it remains focused on delivering precision solutions that meet the unique needs of its customers.The expansion of CNC Precision comes at a time when the manufacturing industry is experiencing rapid growth and transformation. With increasing demand for precision-machined parts and components, companies are seeking reliable partners that can deliver high-quality products with quick turnaround times. CNC Precision's expansion plans align with the industry's needs, positioning the company for continued success and leadership in the precision machining sector.As CNC Precision continues to expand its operations and capabilities, it remains dedicated to delivering exceptional quality and service to its customers. The company's expansion plans underscore its commitment to meeting the evolving needs of the manufacturing industry and driving innovation in precision machining. With its growing team, advanced technology, and strategic partnerships, CNC Precision is well-positioned to continue setting the standard for precision machining and delivering value to its customers.

How Injection Moulding Works: A Comprehensive Guide

Injection Moulder Celebrates Continued Success with Expansion and InnovationWith over 20 years of experience in the plastic injection molding industry, Injection Moulder has established a strong reputation for providing high-quality precision parts for a variety of industries. The company has recently celebrated its continued success with the expansion of its facilities and the introduction of innovative new technologies.Injection Moulder, based in [Location], has built a solid foundation in the plastic injection molding industry with its dedication to delivering top-notch products and exceptional customer service. Specializing in custom injection molding, the company has served a wide range of industries including automotive, medical, consumer products, and industrial manufacturing.The company's commitment to quality and innovation has been evident in its recent expansion efforts. Injection Moulder has invested in a state-of-the-art production facility that has allowed for increased capacity and improved efficiency. This expansion has enabled the company to better serve its growing customer base and to take on more complex and demanding projects.In addition to expanding its facilities, Injection Moulder has also focused on incorporating innovative technologies into its production processes. The company has adopted the latest advancements in injection molding equipment and automation systems, allowing for greater precision, consistency, and speed in manufacturing."We are thrilled to announce the expansion of our facilities and the integration of advanced technologies into our production processes," said [Spokesperson], CEO of Injection Moulder. "These developments have been instrumental in furthering our commitment to delivering high-quality products and exceeding the expectations of our customers."Injection Moulder's dedication to innovation and continuous improvement has not gone unnoticed. The company has received accolades for its exceptional performance and has been recognized as a reliable and trusted partner in the plastic injection molding industry.In addition to its expansion and technological advancements, Injection Moulder has also made strides in sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing processes, including the use of recycled materials and energy-efficient equipment. By prioritizing sustainability, Injection Moulder aims to reduce its environmental impact and contribute to a cleaner and healthier planet.Furthermore, Injection Moulder has placed a strong emphasis on workforce development and employee satisfaction. The company has invested in training programs and professional development opportunities for its employees, fostering a culture of continuous learning and growth. Injection Moulder's team of skilled and dedicated professionals is crucial to the company's success and plays a significant role in delivering exceptional products and services.Looking ahead, Injection Moulder remains committed to staying at the forefront of the plastic injection molding industry. The company is dedicated to exploring new opportunities for growth and innovation, while maintaining its focus on quality, customer satisfaction, and sustainability."We are excited about the future of Injection Moulder and the possibilities that lie ahead," [Spokesperson] added. "As we continue to invest in our capabilities and push the boundaries of what is possible in plastic injection molding, we are confident that Injection Moulder will remain a leader in the industry for years to come."With its expansion, technological advancements, and commitment to excellence, Injection Moulder has solidified its position as a trusted and reliable partner for businesses seeking high-quality plastic injection molding solutions. The company's dedication to innovation, sustainability, and customer satisfaction sets it apart in the industry and paves the way for continued success in the years to come.

Top 5 Factors to Consider When Choosing an Injection Moulding Die

Injection Moulding Die: Revolutionizing the Manufacturing IndustryWith the ever-growing demand for high-quality plastic products in various industries, the manufacturing sector is witnessing a surge in the use of injection moulding dies. These dies have become an indispensable tool in the production of a wide range of plastic components, from automotive parts to consumer goods. One company that has been at the forefront of this revolution is {}, a leading manufacturer of injection moulding dies.Established in {}, {} has been providing innovative solutions to their clients in the manufacturing industry for over {} years. Specializing in the design and fabrication of precision moulds, the company has earned a reputation for delivering high-quality products and exceptional customer service.The injection moulding process involves the use of a moulding die, which is a tool that is used to shape molten plastic into a desired form. The die is comprised of two main parts: the stationary side, known as the cavity, and the moving side, known as the core. When the molten plastic is injected into the die, it is subjected to high pressure, causing it to take the shape of the mould. Once the plastic has cooled and solidified, the die is opened, and the finished product is ejected.{} has been at the forefront of developing advanced injection moulding dies that are capable of producing complex and intricate plastic components with high precision and efficiency. The company's team of skilled engineers and technicians work closely with their clients to understand their specific requirements and provide customized solutions that meet their production needs.The injection moulding dies manufactured by {} are designed to enhance the overall manufacturing process, improving productivity and reducing the production cycle time. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce high-quality moulds with tight tolerances and consistent performance. This has enabled {} to serve a diverse range of industries, including automotive, electronics, medical, and consumer goods.One of the key advantages of using injection moulding dies from {} is the ability to produce large volumes of plastic components with remarkable precision and repeatability. This is particularly beneficial for manufacturers who require consistent quality and uniformity in their products. The company's commitment to continuous innovation and improvement has positioned them as a trusted partner for companies looking to enhance their manufacturing capabilities.In addition to their cutting-edge injection moulding dies, {} also offers comprehensive support services to their clients, including mould maintenance, repair, and refurbishment. This ensures that their clients can maximize the lifespan of their moulds and minimize downtime, ultimately optimizing their production operations.As the demand for high-quality plastic products continues to rise, the role of injection moulding dies in the manufacturing industry becomes increasingly crucial. {} has demonstrated their ability to stay ahead of the curve by delivering top-notch moulds that align with the evolving needs of the industry. By combining their technical expertise, manufacturing capabilities, and customer-oriented approach, the company has established itself as a leader in the injection moulding die market.Looking ahead, {} remains committed to pushing the boundaries of innovation and setting new standards for excellence in the manufacturing sector. The company's dedication to delivering exceptional products and services positions them as a trusted partner for manufacturers seeking to optimize their production processes and stay competitive in the global market.In conclusion, injection moulding dies have undoubtedly revolutionized the manufacturing industry, and {} has been at the forefront of this transformation. With their advanced mould design and fabrication capabilities, the company continues to drive the industry forward, empowering manufacturers to achieve greater efficiency and precision in their production operations.

Top Clear Plastic Molding Techniques for Your Project

Clear Plastic Molding Company, a leading provider of high-quality plastic molding solutions, has been making significant strides in the industry. With a commitment to innovation and excellence, the company has built a strong reputation for delivering top-notch products to its clients. Clear Plastic Molding Company has been in the business for over two decades and has established itself as a trusted partner for businesses in need of custom plastic molding solutions.The company specializes in clear plastic molding, offering a wide range of services including injection molding, blow molding, and thermoforming. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing them to produce complex and intricate plastic parts with precision and efficiency. Whether it's a small run of prototypes or a large-scale production, Clear Plastic Molding Company has the capabilities to meet the needs of their clients.One of the key strengths of Clear Plastic Molding Company is its dedication to quality. The company adheres to strict quality control measures at every step of the manufacturing process to ensure that the final products meet the highest standards. From raw material sourcing to final inspection, Clear Plastic Molding Company goes above and beyond to deliver products that are durable, reliable, and visually appealing.In addition to quality, Clear Plastic Molding Company also prioritizes customer satisfaction. The company has a team of experienced engineers and designers who work closely with clients to understand their specific requirements and deliver custom solutions that meet their needs. From concept and design to production and delivery, Clear Plastic Molding Company provides end-to-end support to its clients, ensuring a smooth and hassle-free experience.Furthermore, Clear Plastic Molding Company is committed to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and utilizes recyclable materials whenever possible, reducing its carbon footprint and contributing to a more sustainable future. Clear Plastic Molding Company understands the importance of environmental conservation and strives to minimize its impact on the planet.Clear Plastic Molding Company has a diverse client base, serving a wide range of industries including automotive, medical, consumer goods, and electronics. The company's ability to adapt to the unique requirements of each industry has earned it a favorable reputation among its clients. Whether it's producing intricate medical device components or durable automotive parts, Clear Plastic Molding Company has the expertise and resources to deliver exceptional results.Looking ahead, Clear Plastic Molding Company is focused on further expanding its capabilities and enhancing its offerings. The company is continuously investing in research and development to stay at the forefront of innovation in plastic molding technology. Additionally, Clear Plastic Molding Company is exploring new opportunities for growth, including potential partnerships and collaborations that will enable it to reach new markets and serve a broader range of clients.In conclusion, Clear Plastic Molding Company is a leading provider of clear plastic molding solutions, known for its commitment to quality, customer satisfaction, and sustainability. With a focus on innovation and excellence, the company has established itself as a trusted partner for businesses in need of custom plastic molding services. As the industry continues to evolve, Clear Plastic Molding Company is well-positioned to thrive and further solidify its position as a top-tier provider of plastic molding solutions.

High-Quality Plastic Injection Tooling: What You Need to Know

Plastic Injection Tooling, a key component in the manufacturing process for a wide range of products, is a critical part of the production line for many companies. It is essential for creating high-quality, precision-engineered plastic components that are used in various industries such as automotive, aerospace, medical, consumer goods, and more. With the market demand for plastic injection tooling on the rise, it's important for companies to have access to reliable and efficient tools that can meet their production needs.{Company Name} is a leading provider of plastic injection tooling solutions, offering a wide range of services to help companies optimize their production processes. From design and engineering to prototype development and mass production, {Company Name} delivers high-quality, cost-effective solutions to meet the unique needs of each customer. With a team of experienced engineers and state-of-the-art facilities, {Company Name} is committed to providing top-notch plastic injection tooling that exceeds customer expectations.One of the key advantages of {Company Name}'s plastic injection tooling solutions is their ability to work with a variety of materials, including traditional thermoplastics, engineering resins, and high-performance materials. This flexibility allows customers to choose the best material for their specific application, whether it's for a high-stress automotive component or a delicate medical device. {Company Name} also offers expertise in designing complex tooling systems that can produce intricate parts with tight tolerances, giving customers the confidence that their products will meet the highest quality standards.In addition to their technical expertise, {Company Name} prides itself on its commitment to customer service and satisfaction. Their team works closely with each customer to understand their unique requirements and objectives, providing personalized solutions that meet their needs and budget. Whether it's a small prototype run or a large-scale production project, {Company Name} is dedicated to delivering the right plastic injection tooling solution on time and within budget.{Company Name} has also invested in cutting-edge technology and equipment to ensure that they stay at the forefront of the industry. Their state-of-the-art manufacturing facilities are equipped with the latest CNC machines, EDM equipment, and mold flow analysis software, allowing them to produce high-quality tooling with precision and efficiency. This technology, combined with their team's expertise, enables {Company Name} to deliver top-notch plastic injection tooling solutions that help their customers stay competitive in the marketplace.As the demand for plastic injection tooling continues to grow, {Company Name} remains committed to innovation and continuous improvement. They are constantly exploring new materials, technologies, and processes to enhance their capabilities and deliver better value to their customers. By staying ahead of industry trends and investing in the latest tools and equipment, {Company Name} aims to remain a trusted partner for companies looking for reliable and efficient plastic injection tooling solutions.Overall, the continued success of {Company Name} is a testament to their dedication to quality, innovation, and customer satisfaction. As the demand for plastic injection tooling continues to rise, companies can rely on {Company Name} to deliver the high-quality, cost-effective solutions they need to stay competitive in the marketplace. With their expertise, state-of-the-art facilities, and commitment to excellence, {Company Name} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the plastic injection tooling market.