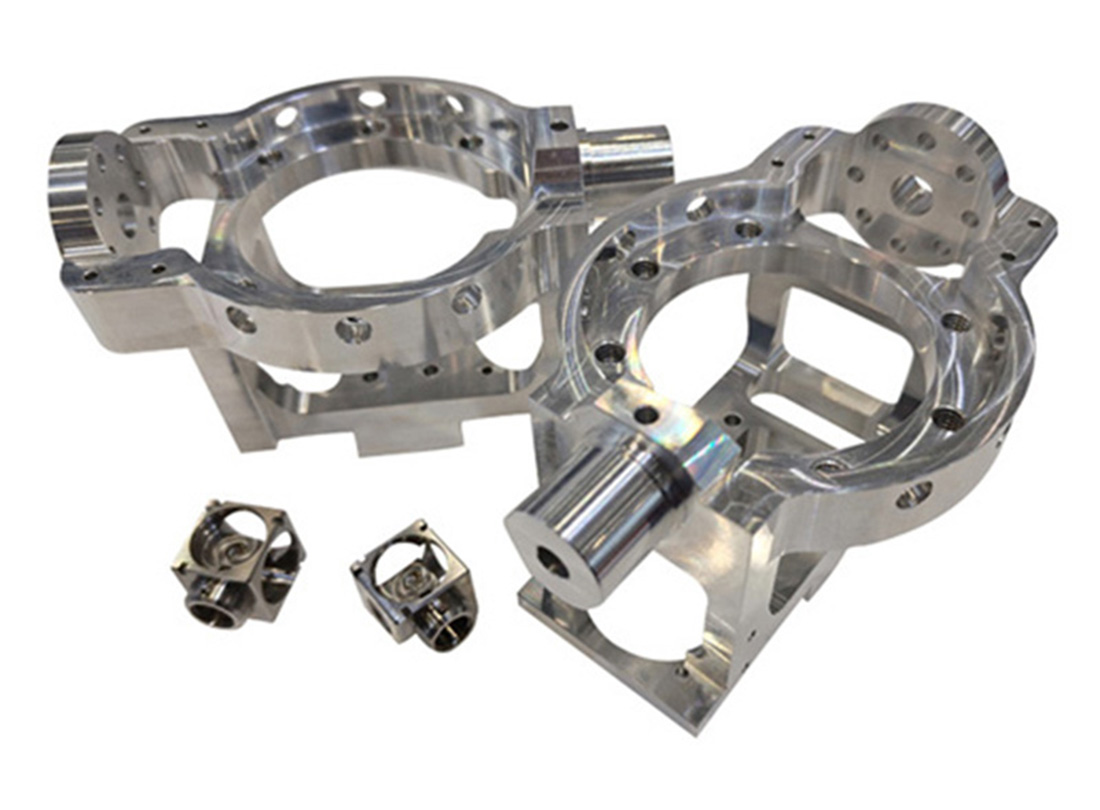

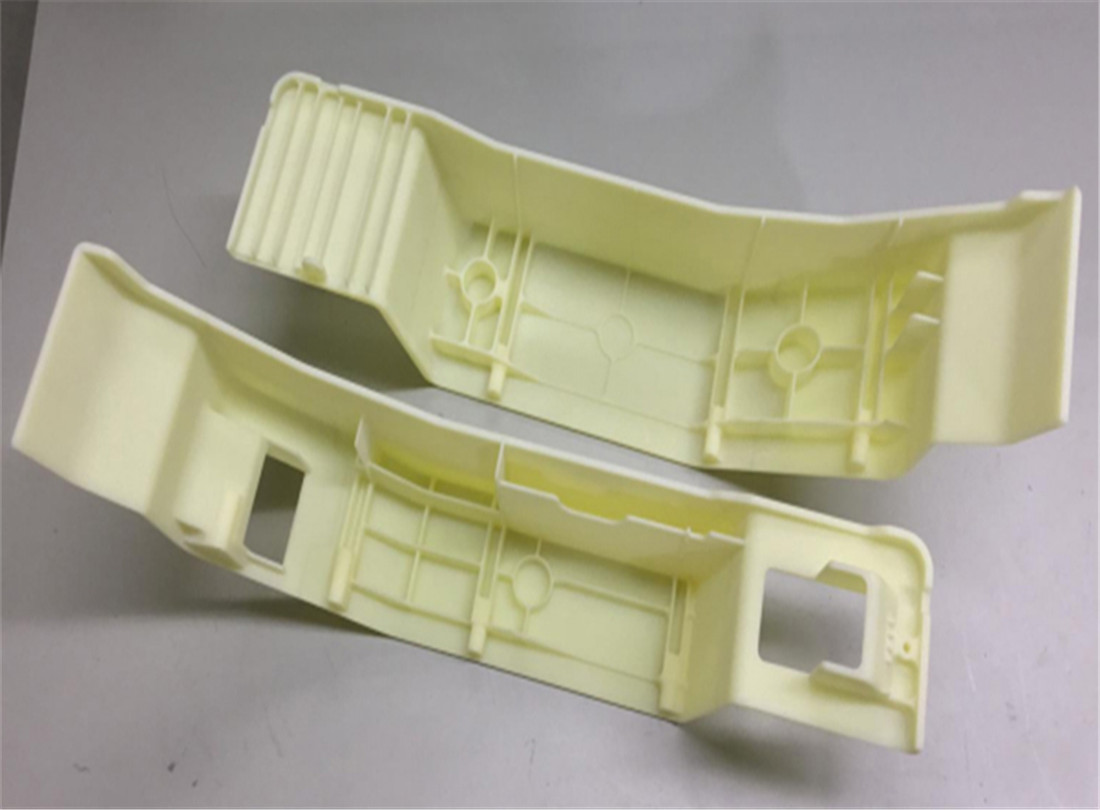

| Material | Aluminum, Stainless Steel, Steel, Brass Cast Iron, Forged Alloy, Tin, Nickel, Plastics, Copper, Bronze | ||||||||

| Max. machining size | 510 * 1020 * 500 mm(max) | ||||||||

| Tolerance | according to 2D drawing requirment, normallly +/-0.005 mm | ||||||||

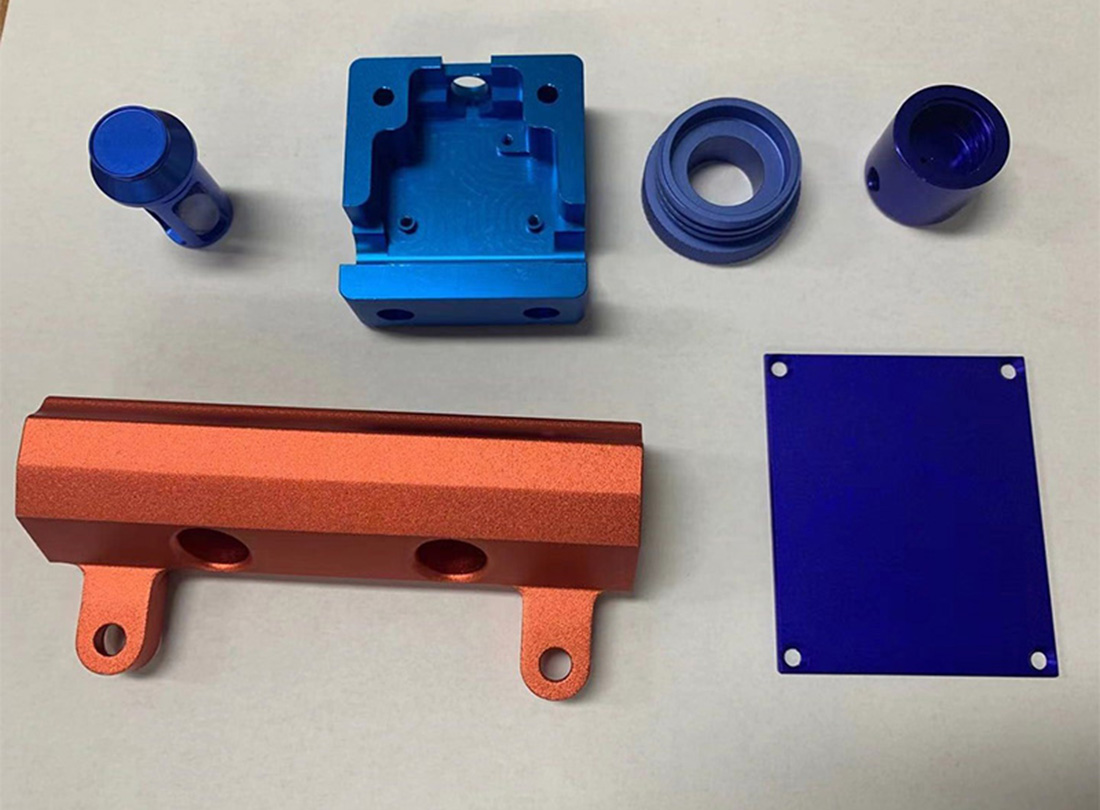

| Surface Treatment | Anodized (Type II Or Type III), chrome plating, silver plating, polishing, galvanized, electroplating, passivation, powder coating, spraying, and painting, etc | ||||||||

| Main Process | CNC machining, turning, lathing, milling, drilling, grinding, boring, stamping, threading, tamping, EDM, wire walking, laser cutting, laser marking, and surface treatment | ||||||||

| Quality Control | Strictly Quality control in the whole process, from material to packing | ||||||||

| Industry CT scanning, 3D projector, X-ray technology, Coordinate-measuring machine | |||||||||

| Volume | 10-10,000 Lot Size | ||||||||

| Usage | Military Parts,Aerospace parts | ||||||||

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted | ||||||||

Cost-effective for complex geometry Excellent speed to market development Specifications of 5-axis high precision Military Parts CNC MachiningCNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.

Cost-effective for complex geometry Excellent speed to market development Specifications of 5-axis high precision Military Parts CNC MachiningCNC machining service provides a significant manufacturing solution for CNC military parts of a diversity of military and defense equipment, like army equipment, navy equipment, military aircraft, military vehicles, ordnance, ship & submarines, air force equipment, marine corps equipment, coast guard equipment, weapons, etc. To meet the high demands and high standard of military instruments, online Highest Level Military Parts CNC Machining CNC machining , advanced processing technique and sophisticated devices to ensure the high efficiency, high precision, tight tolerance, long service life and outstanding performance of the products.

We offer one-stop and quick turnaround CNC machining services, including precision CNC turning, CNC milling, and CNC grinding service. As well as some other secondary machining processes, such as drilling, tapping, boring, honing, knurling, etc. We are capable to manufacture CNC machined parts with custom surface finishes at a competitive price, or provide manufacturing advise to make your custom designed CNC parts more easy to produce and cost-effective. Contact us now for your project of CNC machining parts.

We offer one-stop and quick turnaround CNC machining services, including precision CNC turning, CNC milling, and CNC grinding service. As well as some other secondary machining processes, such as drilling, tapping, boring, honing, knurling, etc. We are capable to manufacture CNC machined parts with custom surface finishes at a competitive price, or provide manufacturing advise to make your custom designed CNC parts more easy to produce and cost-effective. Contact us now for your project of CNC machining parts.